Rear torsion beam suspension discussion.

#1

Rear torsion beam suspension discussion.

Originally Posted by wikipedia

The twist-beam rear suspension, also known as torsion-beam axle is a type of automobile suspension based on a large H or C shaped member. The front of the H attaches to the body via rubber bushings, and the rear of the H carries each stub-axle assembly, on each side of the car. The cross beam of the H holds the two trailing arms together, and provides the roll stiffness of the suspension, by twisting as the two trailing arms move vertically, relative to each other.

The coil springs usually bear on a pad alongside the stub-axle. This location gives them a very high motion ratio compared with most suspensions, which improves their performance, and reduces their weight.

The longitudinal location of the cross beam controls important parameters of the suspension's behaviour, such as the roll steer curve and toe and camber compliance. The closer the cross beam to the axle stubs the more the camber and toe changes under deflection.

A key difference between the camber and toe changes of a twist beam vs independent suspension is the change in camber and toe is dependent on the position of the other wheel, not the car's chassis. In a traditional independent suspension the camber and toe are based on the position of the wheel relative to the body. If both wheels compress together their camber and toe will not change. Thus if both wheels started perpendicular to the road and car compressed together they will stay perpendicular to the road. The camber and toe changes are the result of one wheel being compressed relative to the other.

The coil springs usually bear on a pad alongside the stub-axle. This location gives them a very high motion ratio compared with most suspensions, which improves their performance, and reduces their weight.

The longitudinal location of the cross beam controls important parameters of the suspension's behaviour, such as the roll steer curve and toe and camber compliance. The closer the cross beam to the axle stubs the more the camber and toe changes under deflection.

A key difference between the camber and toe changes of a twist beam vs independent suspension is the change in camber and toe is dependent on the position of the other wheel, not the car's chassis. In a traditional independent suspension the camber and toe are based on the position of the wheel relative to the body. If both wheels compress together their camber and toe will not change. Thus if both wheels started perpendicular to the road and car compressed together they will stay perpendicular to the road. The camber and toe changes are the result of one wheel being compressed relative to the other.

Conceptual model of a twist beam suspension. The green segments illustrate the axle stub centerlines. At rest the axles are in line and the wheels are vertical (Camber = 0 degrees)

The twist beam suspension with the left axle deflected upwards. The deflected wheel now has negative camber. The left and right axles are no longer aligned. The right wheel's camber has changed to positive due to the deflection of the left wheel.

Single wheel deflection (deflection due to roll) vs both wheels up (deflection in bump). Note that when both wheels are deflected the axles remain in line and the wheels have no camber change.

Single wheel deflection shown vs both wheels at rest.

Both wheels shown deflected up (bump) and at rest. Note that the axle halves remain in line and the wheel camber does not change.

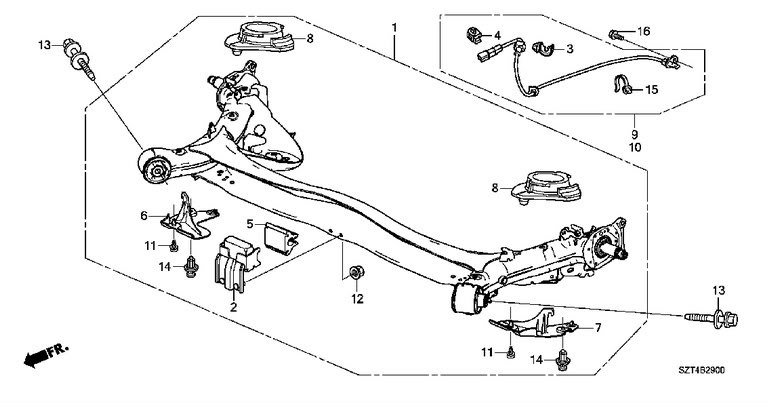

Vs. the CRZ:

[/quote]

[/quote]

#2

I am having a hard time conceptualizing how the comparatively thin Progress rear sway bar will reduce flex in the massive rear trailing arm? Seems like a much more effective (and cheaper) alternative would be to weld in an additional cross member in the rear axle at the location of the rear springs.

Thoughts?

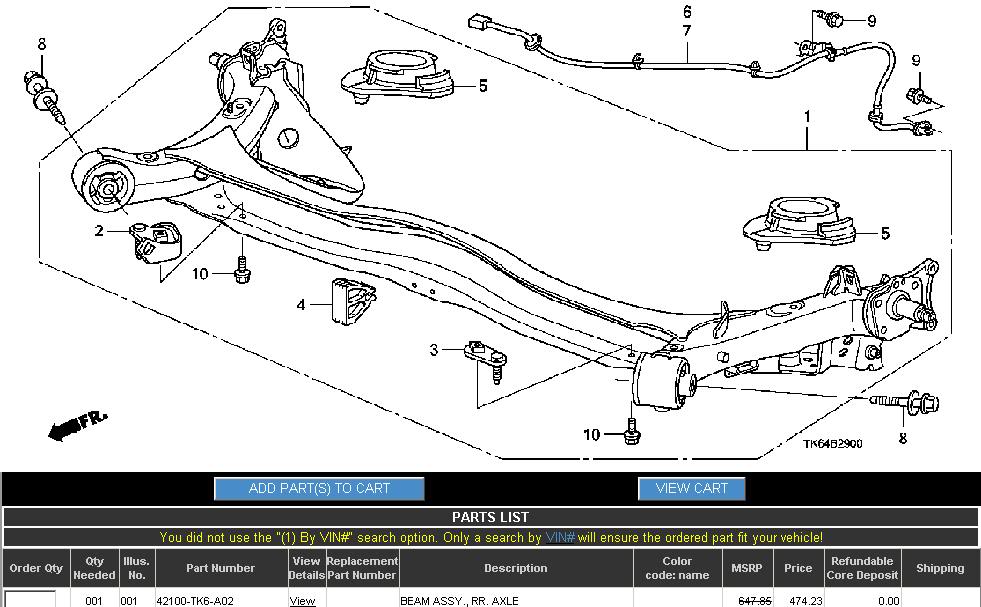

I am unable to find the part # for the Fit Sport RSB...and it does not show on the parts diagram (www.hondapartsdeals.com).

Thoughts?

I am unable to find the part # for the Fit Sport RSB...and it does not show on the parts diagram (www.hondapartsdeals.com).

Last edited by blackndecker; 10-19-2011 at 07:11 PM.

#3

Excellent info here:

http://www.worldautosteel.org/upload...eam_Design.pdf

And here:

http://grassrootsmotorsports.com/for...s/23549/page1/

And here:

http://autospeed.com/cms/title_Rear-...9/article.html

http://www.worldautosteel.org/upload...eam_Design.pdf

And here:

http://grassrootsmotorsports.com/for...s/23549/page1/

And here:

http://autospeed.com/cms/title_Rear-...9/article.html

Last edited by blackndecker; 10-19-2011 at 07:48 PM.

#4

moved...and i'll try to elaborate when i get home. i feel like i have to draw a picture.

it isn't but what the torsion beam does is twist if even just a little bit. the trailing arms are connected to the rest of the car's frame. so the from the front of the suspension to the back is: front of trailing arms connected to frame by bushings, the axle beam and then the rear of the trailing arms where the springs and shocks are seated. the basic way is to picture it as a ladder without the other side connected to the rungs.

it would look like this:

_________________

| | | | | | |

picture the rungs as the trailing arms. without the other side, the rungs are fee to flex up and down. what a sway bar does is add another side to the "ladder".

so it looks like this and it's much more solid and won't flex as much:

______________________

| | | | | | |

-------------------------

i don't even have MSpaint on this work computer.

it would look like this:

_________________

| | | | | | |

picture the rungs as the trailing arms. without the other side, the rungs are fee to flex up and down. what a sway bar does is add another side to the "ladder".

so it looks like this and it's much more solid and won't flex as much:

______________________

| | | | | | |

-------------------------

i don't even have MSpaint on this work computer.

#5

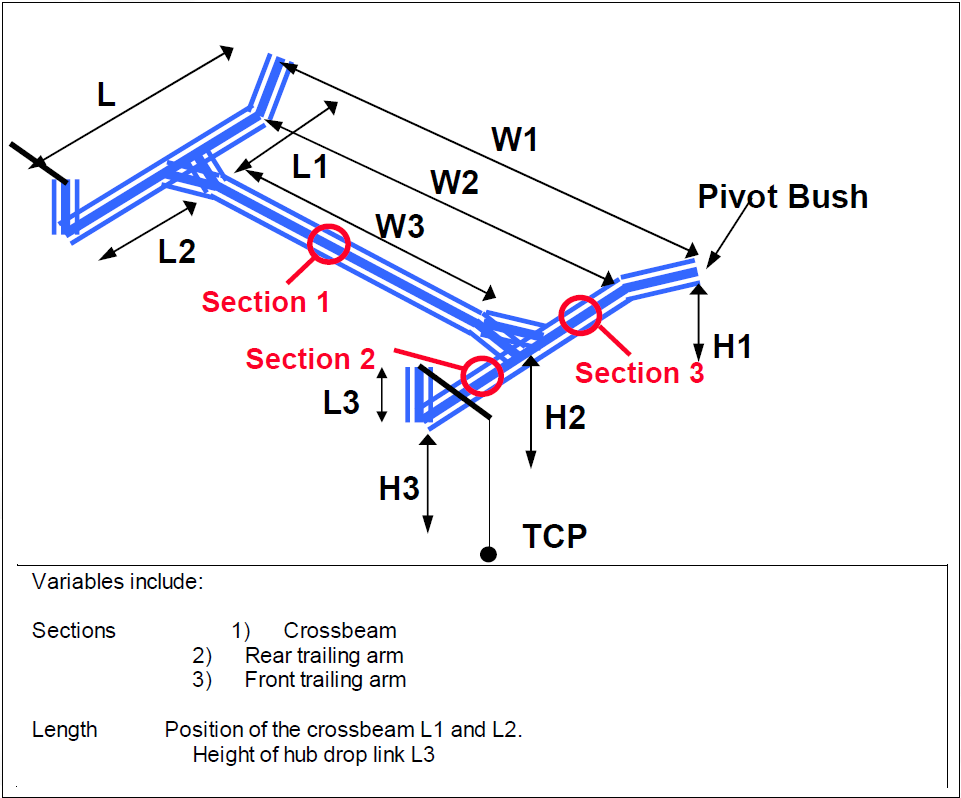

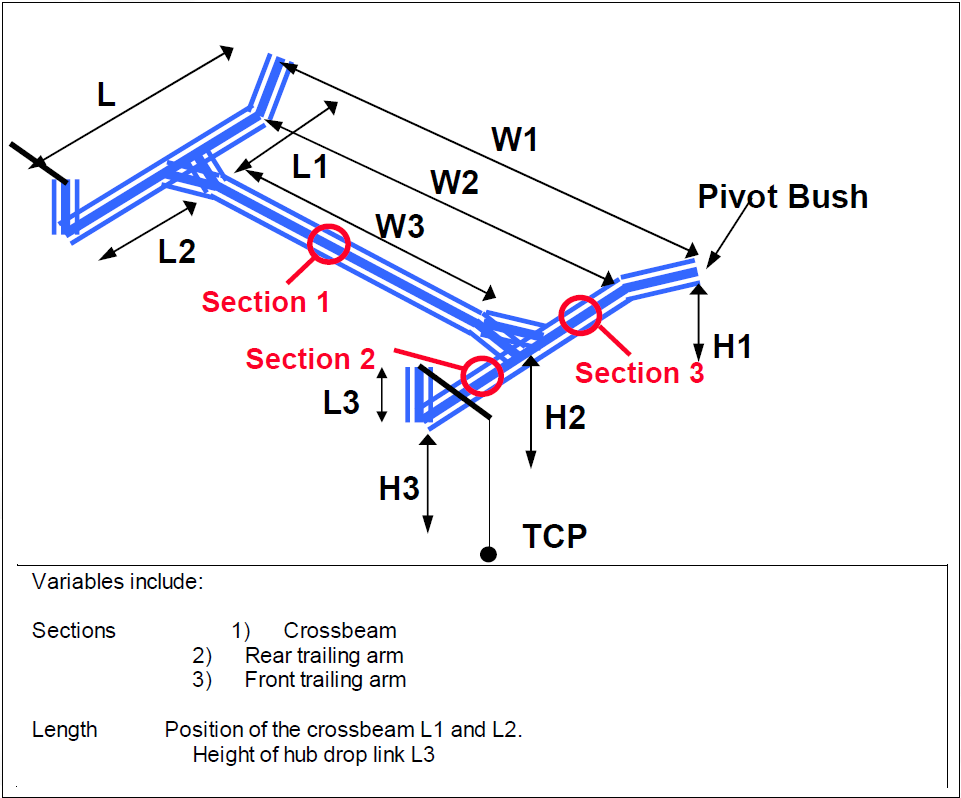

This picture taken from the above pdf will help so that we all use the appropriate nomenclature:

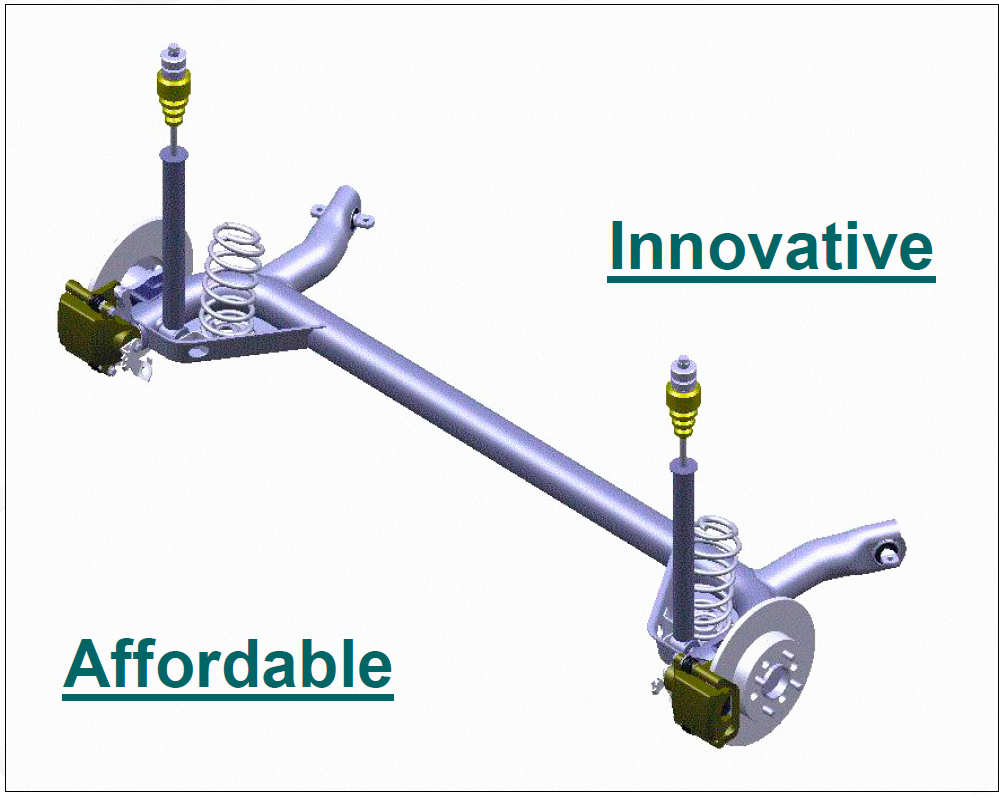

And this is a more realistic depiction of the rear torsion beam (in the same orientation as above^) to help conceptualize:

And this is a more realistic depiction of the rear torsion beam (in the same orientation as above^) to help conceptualize:

Last edited by blackndecker; 10-19-2011 at 07:29 PM.

#6

and to add, the bushings where the front trailing arms are connected to the rest of the frame are made to compress and flex which allows the left and right wheel to move a bit independently from each other. a RSB minimizes this.

#7

well, you have the right idea right there. that's effectively what a RSB is. it's an additional cross member that stiffens up the rear end so that the inside rear wheel is picked up and doesn't drag with the outside rear wheel during cornering. this behavior is already present on a stock FWD car with a torsion beam but a RSB magnifies it.

Last edited by blackndecker; 10-19-2011 at 07:34 PM.

#8

#10

I am having a hard time conceptualizing how the comparatively thin Progress rear sway bar will reduce flex in the massive rear trailing arm? Seems like a much more effective (and cheaper) alternative would be to weld in an additional cross member in the rear axle at the location of the rear springs.

Thoughts?

Thoughts?

Lots of cars have 19mm diameter or smaller sway bars - they all twist - but in doing so, they're also fighting a lot of force. It shouldn't matter that the Fit already has a rear torsion beam, that thing twists too. No matter what the type of suspension, a RSB (even if it's in addition to a torsion beam), will reduce body roll more than having no RSB at all. It's rigidly bolted to each side of the suspension and will take force in order to twist, force that would otherwise be exhibited as body roll.

You could weld an additional crossmember, but that'd probably make it too stiff.

#11

Color me skeptical...but I just have a hard time believing that a RSB the size of my finger is going to reduce flex in the massive rear trailing arm. I think we are on the same page in regards to the theory, but I just don't buy the hype of the Progress RSB.

Polyurethane or spherical bearing would also help stiffen up the rear. I wonder why no aftermarket company has gone that route? Maybe I will give Energy Suspension a call.

Polyurethane or spherical bearing would also help stiffen up the rear. I wonder why no aftermarket company has gone that route? Maybe I will give Energy Suspension a call.

The RSB, as small as it is, is a solid rod, bent into shape. It ALSO requires some amount of force to twist it... let's call that N amount.

When you put those two together, you now need X+N amount of force to twist both of them.

X... is less than 2600 lbs, that's a given. The proof is going over a bump in the road on one side, the back wheels will differ in height because one wheel is over the bump. The car weighs about 2600 lb, spread over 4 wheels. So X could be less than 850 lbs or so. Actually, even less, since the rear is lighter than the front... Less than 750 lb? less than 700?

In any case, you can easy find that a 19 or even 17 mm rod made of the right alloys can take a few hundred lbs of force to twist. These I would assume are maybe what... 100 or so? I mean even as low as 25 lbs... 25 is still a large enough percentage to add to up to 900lbs of force. on the flipside, narrowing the gap to say 100 lbs for the RSB and 700 for the trailing arm, is a HUGE percentage.

Obviously, I don't know the actual specs for both... but this should give you an idea.

#12

@Goobers and doctordoom

I understand what you both are saying. I'm just skeptical the results are as dramatic as people are stating. It would appear that most people who install the RSB have no data (autocross events, track times, etc) to back up their sensational claims. I think a little skepticism is not unwarranted here.

You can add X+N forces all you want, but if it's below the threshold of any measureable effect then the RSB is worthless.

I do appreciate the discussion though. I've learned alot about tosion beam suspensions from the Wiki page as well as the pdf above.

I understand what you both are saying. I'm just skeptical the results are as dramatic as people are stating. It would appear that most people who install the RSB have no data (autocross events, track times, etc) to back up their sensational claims. I think a little skepticism is not unwarranted here.

You can add X+N forces all you want, but if it's below the threshold of any measureable effect then the RSB is worthless.

I do appreciate the discussion though. I've learned alot about tosion beam suspensions from the Wiki page as well as the pdf above.

#14

I will wait till autocross season starts up this spring and install it. If it's pretty straightforward, I could install it for the afternoon runs and run without it for the AM runs. This would allow pretty good back to back testing. Although, one could argue that any improvement of times is the result of becoming more familiar with the track as the day wears on.

#15

But the problem with adding a RSB, is that it can be a "game changer." RSBs can change a normally under steering (or neutral) car into an over steering car. This means that you have to relearn what this new limit is... and it is possible, that due to the over steer, the limit is LOWER. That's if the over steer gets induced sooner with the RSB than the under steer used to without it.

If the RSB is to PROVE that it is benefiting you, a chart has to show that you essentially hit a limit without the RSB... and then managed to get past that limit with the RSB.

then again... just the fact it induces over steer when you would normally encounter under steer is proof that a small bent rod is doing something, even when mounted to a larger frame.

Of course, the preferred result is when the car can perform "harder" turns before under or over steer is induced.

PS. you gotta wonder why Honda would add a 17mm RSB to a Fit... in a location not easily seen, if it didn't prove beneficial (in some way).

#17

late to the party...

i didn't think the progress rsb was dramatic, but certainly noticeable... i also drive a ptgt which has a torsion beam rear but with a different design...

the front trailing arms (arm forward of the axle) are much longer than the fits... this would make the rear softer, but also allow for less alignment changes...

the rear trailing arms (arm rear of the axle) are non-existant... as opposed to the fit... the shock and spring mounts are on the axle itself, which would help to stiffen the rear, but also might allow for some squirely stuff to happen in transitions...

the ptgt also has a watts link on the rear axle to try and defeat lateral motion in high load corners... not an ideal solution, but pretty effective...

i put energy poly bushings at the rear trailing arm mounts, and for the watts link, and the effect was noticeable... more predictable/crisp turn-in, with more stability mid-corner...

the downside to all of this, especially when you see that the torsion beam is effectively a spring without a dampener, then add a sway bar, another dampen-less spring, and the springs themselves, the rear dampeners are asked to do A LOT of work keeping the rear in order... especially in quick transitions and when experiencing mid-corner bumps...

i still think the rsb and poly are a great idea... but in a rear torsion i think the shocks are going to be key...

i didn't think the progress rsb was dramatic, but certainly noticeable... i also drive a ptgt which has a torsion beam rear but with a different design...

the front trailing arms (arm forward of the axle) are much longer than the fits... this would make the rear softer, but also allow for less alignment changes...

the rear trailing arms (arm rear of the axle) are non-existant... as opposed to the fit... the shock and spring mounts are on the axle itself, which would help to stiffen the rear, but also might allow for some squirely stuff to happen in transitions...

the ptgt also has a watts link on the rear axle to try and defeat lateral motion in high load corners... not an ideal solution, but pretty effective...

i put energy poly bushings at the rear trailing arm mounts, and for the watts link, and the effect was noticeable... more predictable/crisp turn-in, with more stability mid-corner...

the downside to all of this, especially when you see that the torsion beam is effectively a spring without a dampener, then add a sway bar, another dampen-less spring, and the springs themselves, the rear dampeners are asked to do A LOT of work keeping the rear in order... especially in quick transitions and when experiencing mid-corner bumps...

i still think the rsb and poly are a great idea... but in a rear torsion i think the shocks are going to be key...

#18

I am very interested in this discussion and am following it.

Jack up your car in the rear and disconnect the shock on one side and press down on the trailing arm with your foot, it bends A LOT with not much force, I tried it when installing springs lol

the fact that the mounting point for the RSB is shaped like an L I think would do a decent job keeping the wheels more parallel in a turn by keeping that bending to a minimum. It's not like it's mounted with one bolt.

I don't think it does as good a job as if the bar was mounted to the chassis somehow but I do think it's better than nothing.

Jack up your car in the rear and disconnect the shock on one side and press down on the trailing arm with your foot, it bends A LOT with not much force, I tried it when installing springs lol

the fact that the mounting point for the RSB is shaped like an L I think would do a decent job keeping the wheels more parallel in a turn by keeping that bending to a minimum. It's not like it's mounted with one bolt.

I don't think it does as good a job as if the bar was mounted to the chassis somehow but I do think it's better than nothing.

#19

@Goobers and doctordoom

I understand what you both are saying. I'm just skeptical the results are as dramatic as people are stating. It would appear that most people who install the RSB have no data (autocross events, track times, etc) to back up their sensational claims. I think a little skepticism is not unwarranted here.

I understand what you both are saying. I'm just skeptical the results are as dramatic as people are stating. It would appear that most people who install the RSB have no data (autocross events, track times, etc) to back up their sensational claims. I think a little skepticism is not unwarranted here.

I do not have a RSB. I have a front lower tie bar brace (control arm brace), a 4-point sub frame brace, and a 4-point mid-chassis ladder brace. I recently got back from a couple days of rat racing with a small group of mixed cars in the mountains of TN & NC. At each break, we realigned (faster/quicker cars move up the chain). Each time I asked the driver behind me if they noticed ANY wheel lift, and all of them said no. I got that feedback from 4 different drivers. I've been running my chassis setup since May and haven't been out with anyone to get the rear-end assessment. Now I know that my plan (to eliminate wheel lift) worked, but the braces do so much more than a RSB alone. The car tracks differently, the under-steer is night and day over stock, it's solid but not harsh, and the braces are the perfect compliment to my Swift springs.

Here's 2 pics where I'm damn near the adhesion limits of my tires. Never once did the rear-end get loose in two days of hard driving. If anything, I was pushing the front end in some of the turns I entered too fast, and the only way to regain control was to change the track by accelerating. FYI - I was beating the shit out of the car (I was TRYING to get squirrely to find the limits), and I scrubbed 1/3 of the tread off the front tires in only 225 miles of driving.

This particular turn allows you to build speed and set the line early to stick the tires/suspension and accelerate through the turn. I was running my tires at 42psi hot. Notice the tire roll - even on the rear tire - I was nearing the limits here.

Here's the apex of that same turn (same photo series). Again, notice that I'm rolling the right rear tire, yet the left rear is firmly planted. No RSB, and haulin' ass the whole way.