L15A running TD05H 14b + Water/Meth?

#141

Why I love AWD, and miss my Talon, it was such a monster off-road and in the snow.  This is just more motivation to get the yokes, drive shaft pieces and diff in the Laser before next summer.. The first video is nuts, but the way it tears across the beach in the second one is just incredible. Feeling all four wheels fighting for grip and crabwalking is just addicting.

This is just more motivation to get the yokes, drive shaft pieces and diff in the Laser before next summer.. The first video is nuts, but the way it tears across the beach in the second one is just incredible. Feeling all four wheels fighting for grip and crabwalking is just addicting.

YouTube - Sand Talon with Slow mo

YouTube - Sand Talon Round 2

These are the same guys who built and sold a turn key 1200whp 540ci twin GT42R sand truck that runs on a E85 w/ Methanol injection

YouTube - For Sale Team English Racing 1200 WHP Twin Turbo Sand truck E85

YouTube - For Sale 1210Whp E85 Twin Turbo Sand Truck

This was pretty impressive as well:

YouTube - Rhino thinks its a Hippo

http://www.youtube.com/watch?v=bpxK2...eature=related

This is just more motivation to get the yokes, drive shaft pieces and diff in the Laser before next summer.. The first video is nuts, but the way it tears across the beach in the second one is just incredible. Feeling all four wheels fighting for grip and crabwalking is just addicting.

This is just more motivation to get the yokes, drive shaft pieces and diff in the Laser before next summer.. The first video is nuts, but the way it tears across the beach in the second one is just incredible. Feeling all four wheels fighting for grip and crabwalking is just addicting.YouTube - Sand Talon with Slow mo

YouTube - Sand Talon Round 2

These are the same guys who built and sold a turn key 1200whp 540ci twin GT42R sand truck that runs on a E85 w/ Methanol injection

YouTube - For Sale Team English Racing 1200 WHP Twin Turbo Sand truck E85

YouTube - For Sale 1210Whp E85 Twin Turbo Sand Truck

This was pretty impressive as well:

YouTube - Rhino thinks its a Hippo

http://www.youtube.com/watch?v=bpxK2...eature=related

Last edited by DiamondStarMonsters; 12-02-2010 at 02:43 AM.

#142

#143

Nice find, and if I am not mistaken that .pdf is dealing with this 80's formula engine, V6 1.5L turbo, there is a black and white photo in the text as well.

Very cool, SB

Very cool, SB

#145

What a billet compressor wheel being made on a 5-axis CNC table might look like:

YouTube - Impeller machining on five axis StarragHeckert machiningcenter

A cool cut-away video of a subaru boxer diesel engine:

http://www.youtube.com/watch?v=-G5Tc...eature=related

YouTube - Impeller machining on five axis StarragHeckert machiningcenter

A cool cut-away video of a subaru boxer diesel engine:

http://www.youtube.com/watch?v=-G5Tc...eature=related

Last edited by DiamondStarMonsters; 12-05-2010 at 01:22 AM.

#146

Are you ready to have your mind f$&@ed?

What's wrong with this picture? The top one is the l15a7 'header' and cat. The bottom one is the r18 one. WTF!? The r18 'header' is narrower and more restrictive. Luckily I can dremel and drill it to work but I am seriously confused on why the r18 is smaller.

What's wrong with this picture? The top one is the l15a7 'header' and cat. The bottom one is the r18 one. WTF!? The r18 'header' is narrower and more restrictive. Luckily I can dremel and drill it to work but I am seriously confused on why the r18 is smaller.

#148

Now for something a bit more technical, and a lot more interesting, especially with the implications it holds for large turbos and small gas engines..

One of the keys to power and efficiency on any engine is keeping up fluid velocity.

High charge velocity and evacuation allow for very high volumetric efficiency, which is usually directly proportional to torque. When you are tuning your car, and you finally take it in to dyno your torque curve should follow your WOT load cell path through the VE table. VEmax = Peak torque. So whatever you can do to flatten or raise the curve will be of huge benefit. Because horsepower = torque over time, the more torque you have at any given part of the rev-range the more power you are creating.

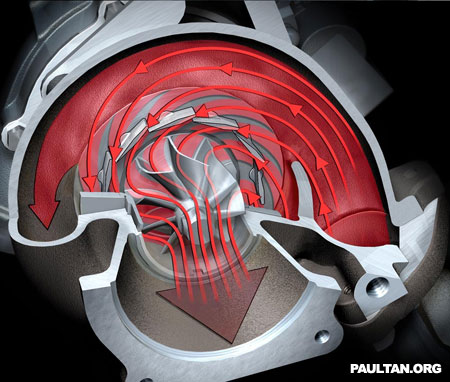

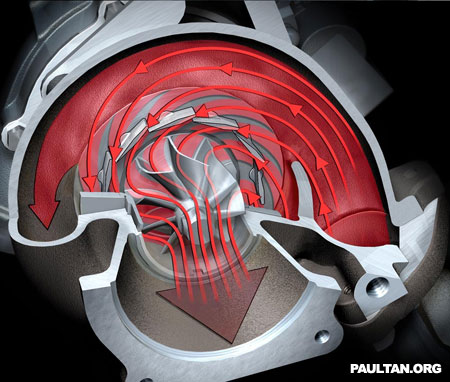

Variable Turbine Nozzle geometry:

YouTube - NUEVA GEOMETRIA VARIABLE EN GARRET TDI 170

YouTube - Turbo variável

YouTube - Porsche 997 VTG - Variable Turbine Geometry

We are dealing with the exhaust side of the turbo here, which is the side that basically determines your power curve or if you can even spool the turbo enough to make boost.

As with most things turbo, this is actually an old technique used in the Diesel world, because for some reason there is a vast disconnect in between the sport/street tuning world and the diesel work truck guys who have been well aware of these things for years..

People forget that even though most long-haul or off-road truckers are not looking to go set any land speed records or 1/4 mile times, they do need to figure out how to get 60tons worth of cargo from point A to B with who knows what obstacles in the way.. let alone get rolling from a standstill in the first place.

Now why this matters to us and our little 1.5L motor and bigger frame turbos..

Diesels while often much larger, higher compression ratio (22:1CR is not unheard of) and produce a great volume of exhaust gasses with which to drive the "hot" side of the turbo, the gasses are actually quite cold and low velocity compared to gasoline ICE engines. Diesels also operate over a much narrower range, which is why the have to multiply that narrow, cliff like torque curve with some serious gearing.

Modern road trucks will often have 18 forward gears.

An old 1950s mack B-series I had when I was younger which had a 5 speed main 4 speed tranfer case and a two speed diff, for a total of 40 possible forward speeds, if that helps illustrate the problem.

So they have had to develop things like variable turbine nozzles, twin scroll turbine housings to isolate exhaust gas pulses and eliminate reversion (natural egr, like on big cam motors)

A "twin scroll" turbine housing, is a divided turbine housing that segregates exhaust pulses so one cylinders exhaust doesn't get into another cylinder during the pressure transition. This not only helps efficiency through more complete comubstion (less retained exhaust gas by better evacuating the cylinders), but it creates absurd amounts of torque through speeding up the "spooling" process.

On the right is a divided housing, on the left is a standard "open" housing, they both have their merits, but there are far more pros to a proper-sized divided housing.

But if you don't run a divided manifold it won't do you any good, and may actually hurt perfomance. The only real downside is you have to run two wastegates as pictured below:

.

.

All of which benefit us because where diesel might consider high EGTs in the 900*F range, a modern aluminum head/piston gas engine doesn't start to enter the danger zone till about 1550*F.

The difference in velocity and charge acceleration is so dramatic large frame turbos like the S259ETT which is normally found on giant 9-14L diesels, yet on my tiny little 2.0L it builds 10psi @ only 3krpm in 2nd gear without any of the above technology. It will even build boost revving at idle!

This is not a ball bearing turbo either, it is a big, beefy journal bearing like you would find on other big diesel turbos.

This bodes well for the Fit because there are cheap T3/T4 and T6 flanged Holset turbos, like the H351VE, which is available as both a twinscroll turbine housing and a variable vane diesel turbo! This would be the ultimate street strip turbo for our Fits, they are cheap, ugly and effective.

For comparison here is an H351VE compared to a 14B like this thread is named after.

Bear in mind that 14B put my Laser into the mid 12s on a stock engine, and about 350lb-ft of torque. The H351VE should spool almost as fast as the 14b, and has the potential for twice the power. Which should mean atleast 150lb-ft or more. Now for the crazy part, the H351VE is only 1mm smaller at the compressor inlet than my 65lb/min BorgWarner S259, yet should spool as fast as a 34lb/min MHI 14B.

This guy attached one to his 2.0L DSM:

http://www.turbotalk.org/bb/viewtopic.php?f=25&t=4

And for those running an insanely large turbo on a very small engine, there is yet another option in addition to tuning trickery and modifications to the "cold" side of the turbo (weight reduction or re-distribution on the compressor wheel), and here it is:

A "quick spool valve," from Sound Performance here in Chicago, and it operates on the same principal as as the variable nozzle vanes described earlier. On the supra they tested they had some remarkable results. This was used to spool a monster T6 GT4508R sized turbo, and they were able to spool so fast they picked up 150whp @ 3300rpm!

http://www.youtube.com/watch?v=I6ZCOTFET6s

Note: Sound Performance is likely not going to get a patent for this, as they are not the original inventors. They just want something to help justify asking supra owners to whip out their checkbooks for this. Several others offer the exhaust same thing for 1/4 the cost, usually less than $200.

Performance Metal Works out of Kentucky for instance.

Here is a dyno graph from another supra picking up a whopping 140lb-ft at the wheels

More detailed information from the Gurus @ NABR:

http://www.teamnabr.com/vbb/showthread.php?t=28918

LS1 Corvette Tech Forums:

http://www.ls1tech.com/forums/forced...ke-graphs.html

The only downside to all of these is that they all require either electronically control solenoids or boost activated diaphragm. So basically you would be operating three wastegate diaphragms.

One of the keys to power and efficiency on any engine is keeping up fluid velocity.

High charge velocity and evacuation allow for very high volumetric efficiency, which is usually directly proportional to torque. When you are tuning your car, and you finally take it in to dyno your torque curve should follow your WOT load cell path through the VE table. VEmax = Peak torque. So whatever you can do to flatten or raise the curve will be of huge benefit. Because horsepower = torque over time, the more torque you have at any given part of the rev-range the more power you are creating.

Variable Turbine Nozzle geometry:

YouTube - NUEVA GEOMETRIA VARIABLE EN GARRET TDI 170

YouTube - Turbo variável

YouTube - Porsche 997 VTG - Variable Turbine Geometry

We are dealing with the exhaust side of the turbo here, which is the side that basically determines your power curve or if you can even spool the turbo enough to make boost.

As with most things turbo, this is actually an old technique used in the Diesel world, because for some reason there is a vast disconnect in between the sport/street tuning world and the diesel work truck guys who have been well aware of these things for years..

People forget that even though most long-haul or off-road truckers are not looking to go set any land speed records or 1/4 mile times, they do need to figure out how to get 60tons worth of cargo from point A to B with who knows what obstacles in the way.. let alone get rolling from a standstill in the first place.

Now why this matters to us and our little 1.5L motor and bigger frame turbos..

Diesels while often much larger, higher compression ratio (22:1CR is not unheard of) and produce a great volume of exhaust gasses with which to drive the "hot" side of the turbo, the gasses are actually quite cold and low velocity compared to gasoline ICE engines. Diesels also operate over a much narrower range, which is why the have to multiply that narrow, cliff like torque curve with some serious gearing.

Modern road trucks will often have 18 forward gears.

An old 1950s mack B-series I had when I was younger which had a 5 speed main 4 speed tranfer case and a two speed diff, for a total of 40 possible forward speeds, if that helps illustrate the problem.

So they have had to develop things like variable turbine nozzles, twin scroll turbine housings to isolate exhaust gas pulses and eliminate reversion (natural egr, like on big cam motors)

A "twin scroll" turbine housing, is a divided turbine housing that segregates exhaust pulses so one cylinders exhaust doesn't get into another cylinder during the pressure transition. This not only helps efficiency through more complete comubstion (less retained exhaust gas by better evacuating the cylinders), but it creates absurd amounts of torque through speeding up the "spooling" process.

On the right is a divided housing, on the left is a standard "open" housing, they both have their merits, but there are far more pros to a proper-sized divided housing.

But if you don't run a divided manifold it won't do you any good, and may actually hurt perfomance. The only real downside is you have to run two wastegates as pictured below:

.

.All of which benefit us because where diesel might consider high EGTs in the 900*F range, a modern aluminum head/piston gas engine doesn't start to enter the danger zone till about 1550*F.

The difference in velocity and charge acceleration is so dramatic large frame turbos like the S259ETT which is normally found on giant 9-14L diesels, yet on my tiny little 2.0L it builds 10psi @ only 3krpm in 2nd gear without any of the above technology. It will even build boost revving at idle!

This is not a ball bearing turbo either, it is a big, beefy journal bearing like you would find on other big diesel turbos.

This bodes well for the Fit because there are cheap T3/T4 and T6 flanged Holset turbos, like the H351VE, which is available as both a twinscroll turbine housing and a variable vane diesel turbo! This would be the ultimate street strip turbo for our Fits, they are cheap, ugly and effective.

For comparison here is an H351VE compared to a 14B like this thread is named after.

Bear in mind that 14B put my Laser into the mid 12s on a stock engine, and about 350lb-ft of torque. The H351VE should spool almost as fast as the 14b, and has the potential for twice the power. Which should mean atleast 150lb-ft or more. Now for the crazy part, the H351VE is only 1mm smaller at the compressor inlet than my 65lb/min BorgWarner S259, yet should spool as fast as a 34lb/min MHI 14B.

This guy attached one to his 2.0L DSM:

http://www.turbotalk.org/bb/viewtopic.php?f=25&t=4

And for those running an insanely large turbo on a very small engine, there is yet another option in addition to tuning trickery and modifications to the "cold" side of the turbo (weight reduction or re-distribution on the compressor wheel), and here it is:

A "quick spool valve," from Sound Performance here in Chicago, and it operates on the same principal as as the variable nozzle vanes described earlier. On the supra they tested they had some remarkable results. This was used to spool a monster T6 GT4508R sized turbo, and they were able to spool so fast they picked up 150whp @ 3300rpm!

http://www.youtube.com/watch?v=I6ZCOTFET6s

Note: Sound Performance is likely not going to get a patent for this, as they are not the original inventors. They just want something to help justify asking supra owners to whip out their checkbooks for this. Several others offer the exhaust same thing for 1/4 the cost, usually less than $200.

Performance Metal Works out of Kentucky for instance.

Here is a dyno graph from another supra picking up a whopping 140lb-ft at the wheels

More detailed information from the Gurus @ NABR:

http://www.teamnabr.com/vbb/showthread.php?t=28918

LS1 Corvette Tech Forums:

http://www.ls1tech.com/forums/forced...ke-graphs.html

The only downside to all of these is that they all require either electronically control solenoids or boost activated diaphragm. So basically you would be operating three wastegate diaphragms.

Last edited by DiamondStarMonsters; 12-05-2010 at 04:54 AM.

#149

Are you ready to have your mind f$&@ed?

What's wrong with this picture? The top one is the l15a7 'header' and cat. The bottom one is the r18 one. WTF!? The r18 'header' is narrower and more restrictive. Luckily I can dremel and drill it to work but I am seriously confused on why the r18 is smaller.

What's wrong with this picture? The top one is the l15a7 'header' and cat. The bottom one is the r18 one. WTF!? The r18 'header' is narrower and more restrictive. Luckily I can dremel and drill it to work but I am seriously confused on why the r18 is smaller.

Edit: copy pasted the link and it worked here goes:

I discovered the hard way a long time ago when I first started doing my own head work, bigger is not always better when it comes to ports. So now that I have looked at this some more, you would probably do just fine if you gave it alot of love from the dremel, gasket matched and then polished the R18 adapter. Then with a nice drill bit or a torch you could make two holes to allow it to mount up to the L15A7 head.

People do routinely this to fit T6 Holset turbine housings onto T4 manifolds. The only question after that is whether or not the R18 adapter puts the turbo in a position where it clears the block, and then you have to clock the compressor cover to clear the firewall and brake lines.

Last edited by DiamondStarMonsters; 12-05-2010 at 04:24 AM.

#150

A quick intro to another topic that I have a certain fondness for, water/methanol/nitrous/propane injection!

Here is a common application, but a fairly expensive version using injection on the intake side of the engine:

Perrin H6 Build up - Complete Results! - NASIOC

Here they have 6 nozzles tapped directly into the intake manifold.

As a failsafe, like many should use on their injection setups, you can see two shut off solenoids mounted on the firewall. This like bottle warmers on nitrous helps maintain line pressure to keep consistent with what you have tuned for!

Here is the progressive controller with two pumps to keep up with their demands on this 3.0 Flat 6.

This slick setup has the progressive computer armed controlled and disconnected from the cabin. Apparently the first switch from the left arms the system, the second reports on the fluid level in the reservoir, the 3rd activates the pre-compressor nozzle, and finally the 4th activates the 6 nozzles located on the intake manifold!

All stuffed into an STi!

Now for an intro on the other recently implemented uses for methanol/nitrous injection on the exhaust side of the engine. In this case, similar to an anti-lag in the sense that fuel is added and timing is retarded to allow combustion to continue on into the exhaust manifold to spool the turbo..

YouTube - Discovery of the Nitrous / Methanol Drag Turbo Anti Lag System

YouTube - The Ultimate Turbo Anti-lag System

http://www.youtube.com/watch?v=NXFmN...eature=related

http://www.youtube.com/watch?v=BZ9eN...eature=related

http://www.youtube.com/watch?v=fzLAe...eature=related

http://www.youtube.com/watch?v=6qUTo...eature=related

Here they are using nitrous and methanol as a sort of afterburner on a small Buick GNX 3.8L V6 turbo that turns 8sec quarter miles, in that they actually inject right at or just before the volute inlet on the turbine where they combust and expand on their way through the turbine wheel building boost with less shock on the thrust surfaces in the turbo and less strain on the turbine shaft its self.

Here is a common application, but a fairly expensive version using injection on the intake side of the engine:

Perrin H6 Build up - Complete Results! - NASIOC

Here they have 6 nozzles tapped directly into the intake manifold.

As a failsafe, like many should use on their injection setups, you can see two shut off solenoids mounted on the firewall. This like bottle warmers on nitrous helps maintain line pressure to keep consistent with what you have tuned for!

Here is the progressive controller with two pumps to keep up with their demands on this 3.0 Flat 6.

This slick setup has the progressive computer armed controlled and disconnected from the cabin. Apparently the first switch from the left arms the system, the second reports on the fluid level in the reservoir, the 3rd activates the pre-compressor nozzle, and finally the 4th activates the 6 nozzles located on the intake manifold!

All stuffed into an STi!

Now for an intro on the other recently implemented uses for methanol/nitrous injection on the exhaust side of the engine. In this case, similar to an anti-lag in the sense that fuel is added and timing is retarded to allow combustion to continue on into the exhaust manifold to spool the turbo..

YouTube - Discovery of the Nitrous / Methanol Drag Turbo Anti Lag System

YouTube - The Ultimate Turbo Anti-lag System

http://www.youtube.com/watch?v=NXFmN...eature=related

http://www.youtube.com/watch?v=BZ9eN...eature=related

http://www.youtube.com/watch?v=fzLAe...eature=related

http://www.youtube.com/watch?v=6qUTo...eature=related

Here they are using nitrous and methanol as a sort of afterburner on a small Buick GNX 3.8L V6 turbo that turns 8sec quarter miles, in that they actually inject right at or just before the volute inlet on the turbine where they combust and expand on their way through the turbine wheel building boost with less shock on the thrust surfaces in the turbo and less strain on the turbine shaft its self.

Last edited by DiamondStarMonsters; 12-05-2010 at 04:45 AM.

#151

If I was to go with a system like that, I am sure my exhaust control valve would become a fast moving projectile unless it was wide open.... I like what it does for turbo lag.... It makes me think of the old Turbonique solid propellant powered turbochargers and turbine engines of the early 1960s.... Those things were insane.

#152

Always looking for info, cant have enough. The thing is old tech is the same as new tech but new tech has more toys to learn about.

#153

I just wish I could afford to run the Honda/ELF Racing blended fuel (84% Toluene, 15% n-Heptane w/ 1%) water in my Laser when I go to Loring and the Maxton Mile next year.

If I can swing it, I want to try the Texas Mile (Maybe I'll stop by and pester Texas Coyote

), but the air temps are so hot for most of the season down there, I don't know if my garage build will be up to snuff for it this season.

), but the air temps are so hot for most of the season down there, I don't know if my garage build will be up to snuff for it this season.The plan is to get some experience at Maxton/Loring while I save up for the spendy safety items I need to in order to get tech'd for my 200mph license.

Then it is off to Bonneville in 2011 or 2012. I am not out to break any records, but the current Production S/C (Super/Turbocharged) record on the salt is held by a 1992 Plymouth Laser from Colorado @ 206mph.

Besides some serious balls, salt driving experience and support staff with our Laser's Coefficient of Drag from the factory, which is something real slippery like .28CoD or .29CoD

Now with the aid of some new components, tight shimming and pre-loads, my stock 5th gear @ 10,200rpm will allow for 226mph, but I will need almost 750whp to get to 226mph.

Again, not trying to break any records, this project is more proof of concept than anything else.

I just wanted to see how fast I can go reliably on a tight budget. I want to be able to drive across the country to the track, be it Auto-X or Standing mile, complete a race, and then drive home under it's own power. I know for a fact the car will see 160mph @ 6750rpm in 5th and pulls like a freight train through that point. With enough power, 5th gear at the stock 7500rpm rev limit gives us ~178mph. My redline is set @ 9250rpm out of concern for floating valves till I get some beehive springs.

With a .29CoD, it theoretically only takes ~260whp to get my DSM up to 180mph. At the time I was on the stock turbo @ 19psi making 330whp/350lb-ft, so it definitely would've done it. There was a 2200lb honda hatch that ran 204.xxx Mph and dyno'd at only 274.x fwhp.

========================================

1. Aerodynamic drag (call it D)

========================================

Assuming ambient air temperature (and therefore density) at about 77 F (25 degrees C) and no wind the equation is then

D = 0.5 x Air Density x Cd x Frontal Area x (Velocity^2)

Air Density at ambient is 1.184 kg/m^3

So D = 0.592 x Cd x Area x (Velocity^2)

========================================

2. Rolling resistance (call it R)

========================================

Assuming passenger car tires at 30 psi on concrete.

R = fr x Weight

fr depends on velocity and is calculated with this equation, which was determined from experiments at the Institute of Technology of Stuttgart:

fr = fzero + 3.24 x fs x (Velocity/100)^2.5

From a chart in my textbook fzero and fs are roughly 0.01 and 0.005. So all you have to do is plug in your velocity, frontal area, and drag coefficient and you'll know how much power it THEORETICALLY takes.

So fr = 0.01 + 0.0162 x (Velocity/100)^2.5

Now, different cars are limited by different factors. Some are drag limited, some are gear limited. This equation simply tells you how much power it would take a vehicle to go a certain speed. If the engine and gearing in that car don't make enough power at that speed, then the car is gearing limited.

Assuming the DSM car has a Cd of 0.29 and Frontal area of 20.4 square feet (which is equal to 1.895 m^2) and weighs 3,000 lbs (13,351 N at sea level) then total drag at 180 mph (which is 80.5 m/s) is:

F = [0.592 x 0.29 x 1.895 x 80.5^2] + [(0.01 + 0.0162 x (80.5/100)^2.5) x 13,351] = 2,108 + 259 = 2,367 N (N is Newtons)

========================================

To calculate Power

========================================

Power is Force x Velocity

W = F x v = 2,367 x 80.5 = 190,544 Watts = 190.5 kW (kiloWatts)

1 kW = 1.34 hp so at 180 mph you need 255 hp

1. Aerodynamic drag (call it D)

========================================

Assuming ambient air temperature (and therefore density) at about 77 F (25 degrees C) and no wind the equation is then

D = 0.5 x Air Density x Cd x Frontal Area x (Velocity^2)

Air Density at ambient is 1.184 kg/m^3

So D = 0.592 x Cd x Area x (Velocity^2)

========================================

2. Rolling resistance (call it R)

========================================

Assuming passenger car tires at 30 psi on concrete.

R = fr x Weight

fr depends on velocity and is calculated with this equation, which was determined from experiments at the Institute of Technology of Stuttgart:

fr = fzero + 3.24 x fs x (Velocity/100)^2.5

From a chart in my textbook fzero and fs are roughly 0.01 and 0.005. So all you have to do is plug in your velocity, frontal area, and drag coefficient and you'll know how much power it THEORETICALLY takes.

So fr = 0.01 + 0.0162 x (Velocity/100)^2.5

Now, different cars are limited by different factors. Some are drag limited, some are gear limited. This equation simply tells you how much power it would take a vehicle to go a certain speed. If the engine and gearing in that car don't make enough power at that speed, then the car is gearing limited.

Assuming the DSM car has a Cd of 0.29 and Frontal area of 20.4 square feet (which is equal to 1.895 m^2) and weighs 3,000 lbs (13,351 N at sea level) then total drag at 180 mph (which is 80.5 m/s) is:

F = [0.592 x 0.29 x 1.895 x 80.5^2] + [(0.01 + 0.0162 x (80.5/100)^2.5) x 13,351] = 2,108 + 259 = 2,367 N (N is Newtons)

========================================

To calculate Power

========================================

Power is Force x Velocity

W = F x v = 2,367 x 80.5 = 190,544 Watts = 190.5 kW (kiloWatts)

1 kW = 1.34 hp so at 180 mph you need 255 hp

This only even happened because I didn't realize how broken my speedometer was till my buddy who was taking datalogs for me started screaming

Now even more encouraging is that as the same Colorado Laser that did 209mph on the salt proved that on pavement it will only take 530fwhp to sling my ~2500lb/0.29CoD DSM to 200mph in a standing mile.

This translates to a high 9sec quartermile @ 150mph!

Last edited by DiamondStarMonsters; 12-06-2010 at 03:13 AM.

#154

Some really neat stuff from that .pdf pretty much re-affirmed my eccentric use of toluene mixed with pump gas.

I just wish I could afford to run the Honda/ELF Racing blended fuel (84% Toluene, 15% n-Heptane w/ 1%) water in my Laser when I go to Loring and the Maxton Mile next year.

If I can swing it, I want to try the Texas Mile (Maybe I'll stop by and pester Texas Coyote ), but the air temps are so hot for most of the season down there, I don't know if my garage build will be up to snuff for it this season.

), but the air temps are so hot for most of the season down there, I don't know if my garage build will be up to snuff for it this season.

I just wish I could afford to run the Honda/ELF Racing blended fuel (84% Toluene, 15% n-Heptane w/ 1%) water in my Laser when I go to Loring and the Maxton Mile next year.

If I can swing it, I want to try the Texas Mile (Maybe I'll stop by and pester Texas Coyote

), but the air temps are so hot for most of the season down there, I don't know if my garage build will be up to snuff for it this season.

), but the air temps are so hot for most of the season down there, I don't know if my garage build will be up to snuff for it this season. Shell sells it too. Shell Racing Fuels - Shell Global Solutions

Shell Racing Fuels - Shell Global Solutions bottom of page.

I'm game for pestering Texas Coyote

#155

Toluene is great stuff in the making of mpg and making turbos spool up too. I do know it expands when heated but in a car unless it has a return fuel line no real advantage of heating the fuel for mpg.

Shell sells it too. Shell Racing Fuels - Shell Global Solutions

Shell Racing Fuels - Shell Global Solutions bottom of page.

I'm game for pestering Texas Coyote

Shell sells it too. Shell Racing Fuels - Shell Global Solutions

Shell Racing Fuels - Shell Global Solutions bottom of page.

I'm game for pestering Texas Coyote

Everyone forgets how involved fueling is and just focus on things like octane. Imagine if we had tried to explain whys and hows of the implication of adding things like Isoheptane, Benzene, Tetraethyl Lead etc. in some of the performance/economy threads that pop up all the time.

Like why, Shells WRC Fuel for Turbo cars can be as low as 95 octane on cars running hot for hours under full load, ridiculously high boost pressure and anti-lagging every single shift (retarding/richening combustion so it continues/occurs into the manifold and turbine volute to spool and maintain boost when the clutch is disengaged)

As you pointed out though, the Toluene I get at paint stores/home depot/lowes is not pure toluene but it certainly does the trick! Mixing with pump 93 helps spread the cost out too. And when I get some tuning bugs sorted out with my new VE table, the Alky kit goes back on, and I begin tuning my Aux Fuel tables all over again

Last edited by DiamondStarMonsters; 12-06-2010 at 08:47 PM.

#156

#157

Shell Racing Solutions names Corey Oil Ltd as new distributor - Shell Global Solutions I believe its about 10 dollars a gallon for shell URT and look they located in north lake. The thing is you use it like octane booster for the most part.

If it is worth it at $10/gal and is any more potent/knock resistant than Q16 @ $9Gal It would certainly be more convenient than shipping and storing a large container of VP Fuels because they tend to go "bad" if the container isn't full and gets opened more than a couple times. Still tough to beat Hardware store Moonshine @ 6-$7/gal haha

Edit: Unfortunately I am entering my last two weeks of the semester so I gotta go get serious on some HW, I'll be in and out tonight though. Find something cool? Post it!

#158

#159

I found this, this is what I wanted to post High Performance Fuels & Additives

Okay had to come back for that... That group offers some really cool products. A 55gallon drum of E95 is only $217!! Or only $1200/barrel for NitroMethane

Think anyone on this forum would buy my FIC BlueMax 1450cc/min injectors to help me pay for some ID2000's (2200cc/min)?

Id still probably need to add another 675cc/min methanol nozzle on top of that because you need ~40% more E95 to burn the same amount of air as Pump 93!

#160

If there were more people with an interest in boosted engines running exotic fuels on the street Silver Bullet could get a HazMat certification and move the ingredients to where they could be mixed then bootlegged the good old way to those in need for the good stuff.