another DIY gone wrong....please help!

#1

another DIY gone wrong....please help!

so I decided to do a valve lash adjustment because of a slight tick and because I wanted to learn how to do it....

results: TPMS light on (maybe because I took a wheel off and the battery out?)might go away if I drive it a bit

-airbag light on....not sure why, I'll check all connections

-engine light on..(scanguage still scanning?)

-engine ticking quite loudly now!!!! (too loose, tight?)

oh yeah and a bolt on the valve cover head snapped...my cousin wanted to torque it I asked him if it was set to 7lbs, he said yeah, turned out it was 27lbs...my bad for trusting him.

Tried removing bolt and it was an issue so I put sealant in that corner to help out. good idea/bad idea?

looks like I'll be going to Honda anyway....

results: TPMS light on (maybe because I took a wheel off and the battery out?)might go away if I drive it a bit

-airbag light on....not sure why, I'll check all connections

-engine light on..(scanguage still scanning?)

-engine ticking quite loudly now!!!! (too loose, tight?)

oh yeah and a bolt on the valve cover head snapped...my cousin wanted to torque it I asked him if it was set to 7lbs, he said yeah, turned out it was 27lbs...my bad for trusting him.

Tried removing bolt and it was an issue so I put sealant in that corner to help out. good idea/bad idea?

looks like I'll be going to Honda anyway....

#2

update.....airbag light and tpms light went away when I circled the block for a test drive....

engine light comes on and off, and D light flashing.....

any idea what to check or what I may have done?

engine light comes on and off, and D light flashing.....

any idea what to check or what I may have done?

#3

latest update....unplugged the scanguage then plugged it in after starting the car....no engine lights and the guage came up quick.

only issues are the fact that my engine is louder now (ticking) and corner bolt (by the timing chain) being snapped and the hole threaded....

should I just take it to honda? or man up and try again?

only issues are the fact that my engine is louder now (ticking) and corner bolt (by the timing chain) being snapped and the hole threaded....

should I just take it to honda? or man up and try again?

#5

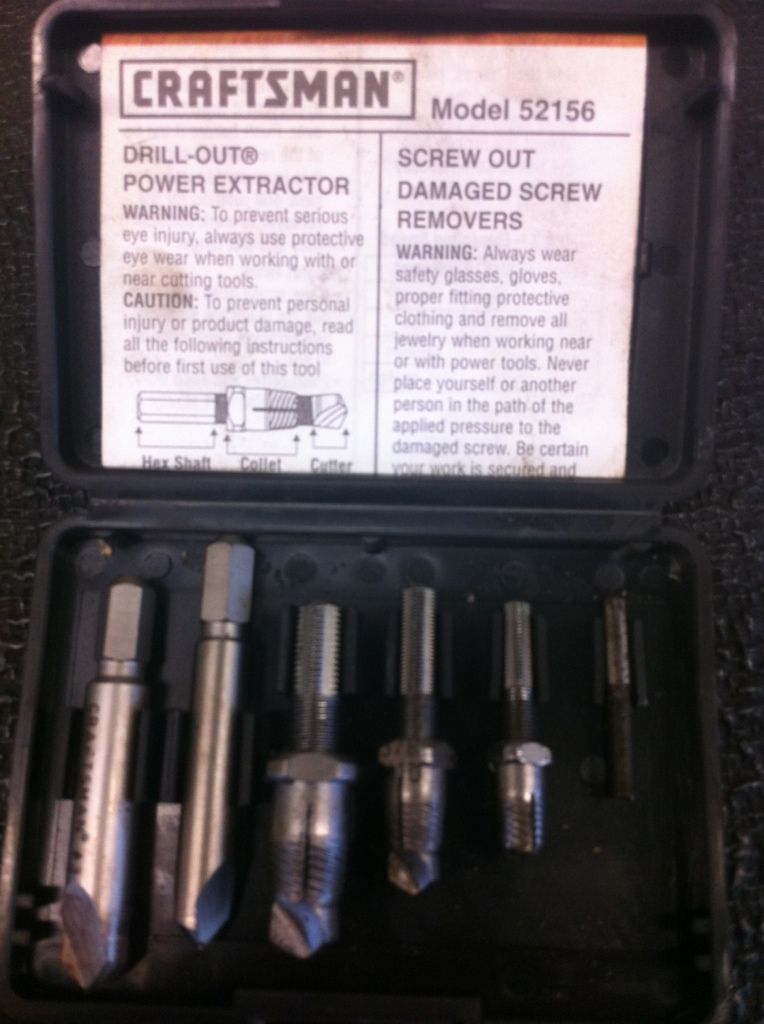

cant really get to the bolt. I tried using a bolt extractor but it ended up hitting the threads a bit also. Not looking good there.

I might have to take it to an independent mechanic to see if they can do it. Worse case scenario, it there a product out there to rethread or at least put another bolt in to hold in place.

I might have to take it all apart again to redo the valves. They are way noisier than before (is that dangerous for the engine?).

Also is it possible the noise will lessen as I drive it? I chose .18m for the intakes and .28 for the exhaust, adjusting them to the point where there was a slight drag as I pulled them out (on the loose side).

I might have to take it to an independent mechanic to see if they can do it. Worse case scenario, it there a product out there to rethread or at least put another bolt in to hold in place.

I might have to take it all apart again to redo the valves. They are way noisier than before (is that dangerous for the engine?).

Also is it possible the noise will lessen as I drive it? I chose .18m for the intakes and .28 for the exhaust, adjusting them to the point where there was a slight drag as I pulled them out (on the loose side).

#7

There are numerous sized extractors.. I don't see why you shouldn't just go ahead and remove the bolt yourself It will be one more skill you acquire in case you trust another family member to touch tools and your car at the same time ever again...You want to be able to hear the exhaust valves clicking a little bit because they will wear into the valve seat over a period of time and the valve adjustment gap clearance will close a little.... You are more likely to have a burned exhaust valve from not having enough clearance and that can get costly if the burnt valve punches a hole in the top of a piston.... I need to do my valves tomorrow....

#9

Yeah as the exhaust valve seat wears the valve stem will move closer to the rocker arms... While you are still messing with it, it might be to your advantage to check the clearance again with Go No Go feeler gauges. If they are too loose the valves will begin to open slower, close slower than they should and not open quite as wide as they should.. Actually that would extend the cam's degrees of duration a little bit and might even pull a little more full into the combustion chamber during over lap when both intake and exhaust valves are both opened at the beginning of the intake stroke... It is less of a problem if the exhaust are a little loose but do try to set them as close to what is recommended for optimal running and wear.

#10

Not that it seems like a big difference, but you want to go looser on the exhaust side and tigher on the intake side.

.28-.30mm Exhaust side

and .16mm on the Intake

.28-.30mm Exhaust side

and .16mm on the Intake

#11

the aftermath

so I about to head to home depot to see if they have a t bar hand extractor. My drill bit one pretty much banged into the threads and I'll probably have to repair the threads.

anyone here experienced in thread repair? what is cutting oil? think I can repair this without taking everything out?

I went to the local mechanic hoping they could get it out with little fuss but they want to remove everything including the upper intake and the valve cover...of course they will charge for all that. When a mechanic says its going to be a big job, hide the wallet!!!!

anyway please feel free to chip in if you've been down this road before. I had no idea those valve ccover bolts were so fragile nor the engine head so soft...

anyone here experienced in thread repair? what is cutting oil? think I can repair this without taking everything out?

I went to the local mechanic hoping they could get it out with little fuss but they want to remove everything including the upper intake and the valve cover...of course they will charge for all that. When a mechanic says its going to be a big job, hide the wallet!!!!

anyway please feel free to chip in if you've been down this road before. I had no idea those valve ccover bolts were so fragile nor the engine head so soft...

#12

I don't see why you shouldn't just go ahead and remove the bolt yourself It will be one more skill you acquire in case you trust another family member to touch tools and your car at the same time ever again...You want to be able to hear the exhaust valves clicking a little bit because they will wear into the valve seat over a period of time and the valve adjustment gap clearance will close a little

#13

Yeah you all are right. Time to man up and try to remove it myself. I need to get proper supplies and may have to try to repair the thread on my own but I hope I can get it right. Time to hit up my local harbor freight and bernardi for supplies.

Meanwhile while my car sounds like a true diesel, it feels better. I pulls smoother, but it could be my imagination.

Meanwhile while my car sounds like a true diesel, it feels better. I pulls smoother, but it could be my imagination.

#16

555: its ok, you never know.....but yeah I did it by the fit service manual and the DIY posted here.

The gray area and I guess what is referred to as the art is getting the amount of drag right. Most of my intakes grabbed the .18mm lightly so that as i passed the feeler back and forth, there was a grab.

The exhausts on the other hand were tight to the point where I had to loosen them, put the feeler in and then tighten when the amount of drag was felt.

I've driven 80 miles since the adjustment and while the car feels good, it is loud (tickey tack). How long does it take to quiet up? otherwise I may have to do it again, and make the intakes tighter and the exhausts.

The gray area and I guess what is referred to as the art is getting the amount of drag right. Most of my intakes grabbed the .18mm lightly so that as i passed the feeler back and forth, there was a grab.

The exhausts on the other hand were tight to the point where I had to loosen them, put the feeler in and then tighten when the amount of drag was felt.

I've driven 80 miles since the adjustment and while the car feels good, it is loud (tickey tack). How long does it take to quiet up? otherwise I may have to do it again, and make the intakes tighter and the exhausts.

#17

If you have a mig welder [or somebody that has one] and can get to the bolt, tack weld a nut [weld inside it] on the broken bolt. Remove right after welding when everything is hot. The best way to extract a broken bolt!

Good luck

Good luck

Last edited by GE8749EW; 03-19-2012 at 03:13 PM.

#18

555: its ok, you never know.....but yeah I did it by the fit service manual and the DIY posted here.

The gray area and I guess what is referred to as the art is getting the amount of drag right. Most of my intakes grabbed the .18mm lightly so that as i passed the feeler back and forth, there was a grab.

The exhausts on the other hand were tight to the point where I had to loosen them, put the feeler in and then tighten when the amount of drag was felt.

I've driven 80 miles since the adjustment and while the car feels good, it is loud (tickey tack). How long does it take to quiet up? otherwise I may have to do it again, and make the intakes tighter and the exhausts.

The gray area and I guess what is referred to as the art is getting the amount of drag right. Most of my intakes grabbed the .18mm lightly so that as i passed the feeler back and forth, there was a grab.

The exhausts on the other hand were tight to the point where I had to loosen them, put the feeler in and then tighten when the amount of drag was felt.

I've driven 80 miles since the adjustment and while the car feels good, it is loud (tickey tack). How long does it take to quiet up? otherwise I may have to do it again, and make the intakes tighter and the exhausts.

#19

Yeah DSM, I agree with you. The ticking I'm hearing is tighter than before, especially when easing off the throttle. Honestly I like it.

If I need to remove the valve cover to get this bolt out I'll just go by your recommendations and tighten up the intakes a smidge. Since I allowed a lighter drag when using the .18mm feelers, I guess I went looser.

but I need to focus on the bolt now....I went to an independent shop and the guy declined the job.... recommended tapping the side of the engine when the bolt is and putting wd-40 in the hole in an attempt to get it all penetrated. Then he recommends using a center punch to level out my previous mess and create space for the extractor to work. What do you guys think? He went against the weld idea, but I'll look around for a machine shop just in case

In a moment of weakness this morning I went to Honda. Without looking at it they said they would do a valve adjustment, extract the bolt and repair the threads for just under $500...but of course that'll change when they look at it. Also I would have to wait a week for the valve cover gasket....

so I ended up ordering the gasket, some cowl clips (after removing it like 4 times already they are beat up) some extra valve cover bolts, and some other pending items to maximize shipping ($144 for everything). I'll regroup and probably tackle the thread myself again.

If I need to remove the valve cover to get this bolt out I'll just go by your recommendations and tighten up the intakes a smidge. Since I allowed a lighter drag when using the .18mm feelers, I guess I went looser.

but I need to focus on the bolt now....I went to an independent shop and the guy declined the job.... recommended tapping the side of the engine when the bolt is and putting wd-40 in the hole in an attempt to get it all penetrated. Then he recommends using a center punch to level out my previous mess and create space for the extractor to work. What do you guys think? He went against the weld idea, but I'll look around for a machine shop just in case

In a moment of weakness this morning I went to Honda. Without looking at it they said they would do a valve adjustment, extract the bolt and repair the threads for just under $500...but of course that'll change when they look at it. Also I would have to wait a week for the valve cover gasket....

so I ended up ordering the gasket, some cowl clips (after removing it like 4 times already they are beat up) some extra valve cover bolts, and some other pending items to maximize shipping ($144 for everything). I'll regroup and probably tackle the thread myself again.

[/IMG]

[/IMG]