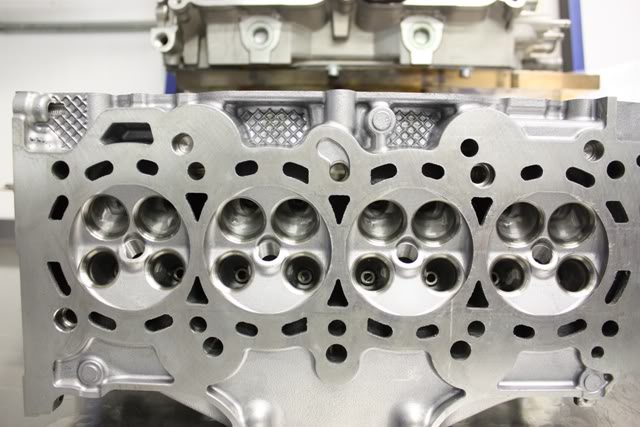

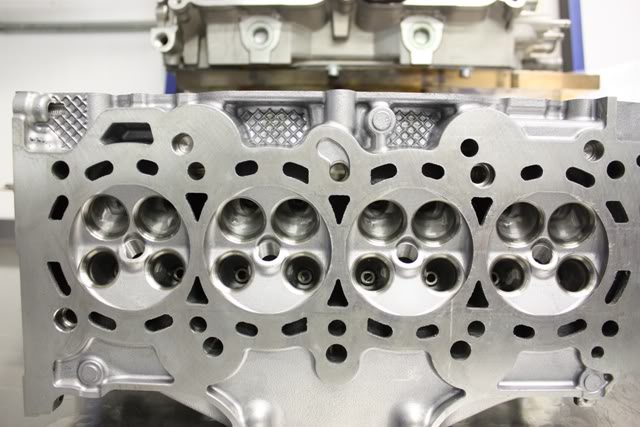

has anyone tried working the head....giggle.

#21

#23

So here's my question. Knowing that the Vtech system works via timing to allow ignition and air flow to change, is there a controller type of product that would disengage it from the ealry vtech hit (which when looking at my old creased, greased and crumpled dynojet pull that the wife found in a box last night), yes, there is a trq hump with a power drop around the mid threes but It still seems like the focus is above 4000.

It would be interesting to see if the camshafts that are available would net anything below 4200 (my thoughts are there would be a loss of power until about 5100).

Having a TRQ specific cam would be nice...time to call up COMP and see what they can do LOL

-Mark

It would be interesting to see if the camshafts that are available would net anything below 4200 (my thoughts are there would be a loss of power until about 5100).

Having a TRQ specific cam would be nice...time to call up COMP and see what they can do LOL

-Mark

#26

Im not entirely certain you guys have nailed down what fluid effects VTEC has or why/when it activates.

Spark timing its self does not determine VTEC activation, more accurately its the other way around... spark timing is changed to accomodate the different loads and weird spikes/dips in airflow at the transition points and there are usually at least 5 bits that make up the ECUs criteria for changing the cam lobe and/or valve activation depending on which version of VTEC we are discussing.

Just the act of moving VTEC higher or lower without using it to accommodate intentional changes to VE and logging that data to compare before and after will not do you much good

Which is why just activating it sooner or later then OE settings on a stock setup for example will usually net poorer than original performance. Especially when combined with Open Loop operation that is forcing the motor to use the existing fuel/timing/VE tables with the now modified VE from the change in VTECs activation point

This is even more dramatic in models that use cam phasing in addition to valve actuation and-or seperate Hi/Lo cam lobes, especially DOHC

The ECU is looking for the "correct" combination of values from the ECT, TPS and VSS sensors, as well as oil pressure seen at the VTEC Solenoid and of course engine RPM.

If you are going to play with VTEC do it on a dyno or on a specific stretch of level straight road and you will need a way to alter the tune as you are directly affecting VE and not necessarily for the better

There are certain windows of charge face velocity as it enters the ports/bowls that are beneficial, and it usually just approaching .5 mach depending on the head design and what sort of valve/cam variation we have available

Same thing on the exhaust side, what most people mistakenly refer to as "proper backpressure" is actually proper wave/pulse tuning in that you are using the timing of the pressure differential across the pulse of each individual cylinder to pull along the one that follows to help evacuate the cylinder more efficiently. This is also neglecting wave/harmonics tuning but that I will have to save for another day as I am too busy lately hence my lack of activity on FF...

Its all about charge and exhaust face velocity. Which is why the GEs get screwed with the integrated exhaust manifold in the cylinder head. You would be able to tune runner/port length and diameter for a specific volume flow and speed to alter VE for whatever your goals/needs are.

In some cases you use this to draw intake air in with greater than 100% VE when you can also align the valve events to this effect.

Two strokes use this effect commonly to "supercharge" themselves

Which Gen Fit do you have Mark?

/I will clean this up when I get home, just a streaming conscious thought that came out like diarrhea when I stumbled on this thread again. Haven't posted tech info in a while

Spark timing its self does not determine VTEC activation, more accurately its the other way around... spark timing is changed to accomodate the different loads and weird spikes/dips in airflow at the transition points and there are usually at least 5 bits that make up the ECUs criteria for changing the cam lobe and/or valve activation depending on which version of VTEC we are discussing.

Just the act of moving VTEC higher or lower without using it to accommodate intentional changes to VE and logging that data to compare before and after will not do you much good

Which is why just activating it sooner or later then OE settings on a stock setup for example will usually net poorer than original performance. Especially when combined with Open Loop operation that is forcing the motor to use the existing fuel/timing/VE tables with the now modified VE from the change in VTECs activation point

This is even more dramatic in models that use cam phasing in addition to valve actuation and-or seperate Hi/Lo cam lobes, especially DOHC

The ECU is looking for the "correct" combination of values from the ECT, TPS and VSS sensors, as well as oil pressure seen at the VTEC Solenoid and of course engine RPM.

If you are going to play with VTEC do it on a dyno or on a specific stretch of level straight road and you will need a way to alter the tune as you are directly affecting VE and not necessarily for the better

There are certain windows of charge face velocity as it enters the ports/bowls that are beneficial, and it usually just approaching .5 mach depending on the head design and what sort of valve/cam variation we have available

Same thing on the exhaust side, what most people mistakenly refer to as "proper backpressure" is actually proper wave/pulse tuning in that you are using the timing of the pressure differential across the pulse of each individual cylinder to pull along the one that follows to help evacuate the cylinder more efficiently. This is also neglecting wave/harmonics tuning but that I will have to save for another day as I am too busy lately hence my lack of activity on FF...

Its all about charge and exhaust face velocity. Which is why the GEs get screwed with the integrated exhaust manifold in the cylinder head. You would be able to tune runner/port length and diameter for a specific volume flow and speed to alter VE for whatever your goals/needs are.

In some cases you use this to draw intake air in with greater than 100% VE when you can also align the valve events to this effect.

Two strokes use this effect commonly to "supercharge" themselves

Which Gen Fit do you have Mark?

/I will clean this up when I get home, just a streaming conscious thought that came out like diarrhea when I stumbled on this thread again. Haven't posted tech info in a while

#27

It's a GE model.

Thank you for the input, yes, the tuner at our facility would be accommodating everything necessary. The vehicle will be run via Haltech and after the wiring will be done, we'll get a glimpse of everything that we can do with the revised head, intake manifold, intake, exhaust and possibly (turbo kit if someone can help me out with getting the hot pipes for it) or waste the money that will be invested and mock up a K swap.

I'm not trying to step on toes, I would just like to understand your point that you made of why people actually manipulate Vtech without adjustments to the rest of the mapping?

I've dealt with tuning for a few years and understand EFI fairly well, I understand the mapping of timing (retardation and advancement), fuel, ignition, dead times (specifically with subaru's) knock sums and values but what I still don't get is why there are specific controllers (or outputs available for Vtech control) that don't have automated adjustments for the fuel and timing maps?

I have noticed that the output from flow compared to the value of power in teh fits is almost 1.1 as far as power availability. The factory engine itself doesn't have much power left in it from the factory which to me is surprising as (a while back) you could take a stock civic to almost 20hp over factory with basic tuning. I'm surprised Honda was allowed to run the engine with basically everything it has. There are two richened spots I see on the maps which I could only gather it being from the Vtech itself (for what you were saying and my thought could be) being a DBW system and Honda not allowing there to be any control over that input.

I'm intrigued in the new version of Honda tuning now since I've really been out of Honda's since I built my K20B/K24H Turbo EG for Nopi years ago. Been messing around with these Evo's and STI's for so long, forgot how a Honda works LOLOL. Man, feel old!

I will send you over a PM for something I'd like some help in pretty soon as you were the first person to explain that Vtech control is moot without proper adjustments. I'm glad we could talk. Now I have to get back to work and figure out why this AMS1000 Boost controller isn't working up top at 80+% WGD and keeps creeping on me. Maybe time to call Tial again for another wastegate rebuild.

Thank you so much for the help on here guys, I'm honestly excited (rather than frustrated) about the Fit build again! Maybe I'll stick with for the long haul for the season. Just need to finally finish it!

BTW, any tips with exterior aero? Need a wider rear QP and don't know if anyone is bombing out these cars like that yet (need to run a slightly larger tire since I'm going down in size to control oversteer)

-Mark

Thank you for the input, yes, the tuner at our facility would be accommodating everything necessary. The vehicle will be run via Haltech and after the wiring will be done, we'll get a glimpse of everything that we can do with the revised head, intake manifold, intake, exhaust and possibly (turbo kit if someone can help me out with getting the hot pipes for it) or waste the money that will be invested and mock up a K swap.

I'm not trying to step on toes, I would just like to understand your point that you made of why people actually manipulate Vtech without adjustments to the rest of the mapping?

I've dealt with tuning for a few years and understand EFI fairly well, I understand the mapping of timing (retardation and advancement), fuel, ignition, dead times (specifically with subaru's) knock sums and values but what I still don't get is why there are specific controllers (or outputs available for Vtech control) that don't have automated adjustments for the fuel and timing maps?

I have noticed that the output from flow compared to the value of power in teh fits is almost 1.1 as far as power availability. The factory engine itself doesn't have much power left in it from the factory which to me is surprising as (a while back) you could take a stock civic to almost 20hp over factory with basic tuning. I'm surprised Honda was allowed to run the engine with basically everything it has. There are two richened spots I see on the maps which I could only gather it being from the Vtech itself (for what you were saying and my thought could be) being a DBW system and Honda not allowing there to be any control over that input.

I'm intrigued in the new version of Honda tuning now since I've really been out of Honda's since I built my K20B/K24H Turbo EG for Nopi years ago. Been messing around with these Evo's and STI's for so long, forgot how a Honda works LOLOL. Man, feel old!

I will send you over a PM for something I'd like some help in pretty soon as you were the first person to explain that Vtech control is moot without proper adjustments. I'm glad we could talk. Now I have to get back to work and figure out why this AMS1000 Boost controller isn't working up top at 80+% WGD and keeps creeping on me. Maybe time to call Tial again for another wastegate rebuild.

Thank you so much for the help on here guys, I'm honestly excited (rather than frustrated) about the Fit build again! Maybe I'll stick with for the long haul for the season. Just need to finally finish it!

BTW, any tips with exterior aero? Need a wider rear QP and don't know if anyone is bombing out these cars like that yet (need to run a slightly larger tire since I'm going down in size to control oversteer)

-Mark

#29

Im not entirely certain you guys have nailed down what fluid effects VTEC has or why/when it activates.

Spark timing its self does not determine VTEC activation, more accurately its the other way around... spark timing is changed to accomodate the different loads and weird spikes/dips in airflow at the transition points and there are usually at least 5 bits that make up the ECUs criteria for changing the cam lobe and/or valve activation depending on which version of VTEC we are discussing.

Just the act of moving VTEC higher or lower without using it to accommodate intentional changes to VE and logging that data to compare before and after will not do you much good

Which is why just activating it sooner or later then OE settings on a stock setup for example will usually net poorer than original performance. Especially when combined with Open Loop operation that is forcing the motor to use the existing fuel/timing/VE tables with the now modified VE from the change in VTECs activation point

This is even more dramatic in models that use cam phasing in addition to valve actuation and-or seperate Hi/Lo cam lobes, especially DOHC

The ECU is looking for the "correct" combination of values from the ECT, TPS and VSS sensors, as well as oil pressure seen at the VTEC Solenoid and of course engine RPM.

If you are going to play with VTEC do it on a dyno or on a specific stretch of level straight road and you will need a way to alter the tune as you are directly affecting VE and not necessarily for the better

There are certain windows of charge face velocity as it enters the ports/bowls that are beneficial, and it usually just approaching .5 mach depending on the head design and what sort of valve/cam variation we have available

Same thing on the exhaust side, what most people mistakenly refer to as "proper backpressure" is actually proper wave/pulse tuning in that you are using the timing of the pressure differential across the pulse of each individual cylinder to pull along the one that follows to help evacuate the cylinder more efficiently. This is also neglecting wave/harmonics tuning but that I will have to save for another day as I am too busy lately hence my lack of activity on FF...

Its all about charge and exhaust face velocity. Which is why the GEs get screwed with the integrated exhaust manifold in the cylinder head. You would be able to tune runner/port length and diameter for a specific volume flow and speed to alter VE for whatever your goals/needs are.

In some cases you use this to draw intake air in with greater than 100% VE when you can also align the valve events to this effect.

Two strokes use this effect commonly to "supercharge" themselves

Which Gen Fit do you have Mark?

/I will clean this up when I get home, just a streaming conscious thought that came out like diarrhea when I stumbled on this thread again. Haven't posted tech info in a while

Spark timing its self does not determine VTEC activation, more accurately its the other way around... spark timing is changed to accomodate the different loads and weird spikes/dips in airflow at the transition points and there are usually at least 5 bits that make up the ECUs criteria for changing the cam lobe and/or valve activation depending on which version of VTEC we are discussing.

Just the act of moving VTEC higher or lower without using it to accommodate intentional changes to VE and logging that data to compare before and after will not do you much good

Which is why just activating it sooner or later then OE settings on a stock setup for example will usually net poorer than original performance. Especially when combined with Open Loop operation that is forcing the motor to use the existing fuel/timing/VE tables with the now modified VE from the change in VTECs activation point

This is even more dramatic in models that use cam phasing in addition to valve actuation and-or seperate Hi/Lo cam lobes, especially DOHC

The ECU is looking for the "correct" combination of values from the ECT, TPS and VSS sensors, as well as oil pressure seen at the VTEC Solenoid and of course engine RPM.

If you are going to play with VTEC do it on a dyno or on a specific stretch of level straight road and you will need a way to alter the tune as you are directly affecting VE and not necessarily for the better

There are certain windows of charge face velocity as it enters the ports/bowls that are beneficial, and it usually just approaching .5 mach depending on the head design and what sort of valve/cam variation we have available

Same thing on the exhaust side, what most people mistakenly refer to as "proper backpressure" is actually proper wave/pulse tuning in that you are using the timing of the pressure differential across the pulse of each individual cylinder to pull along the one that follows to help evacuate the cylinder more efficiently. This is also neglecting wave/harmonics tuning but that I will have to save for another day as I am too busy lately hence my lack of activity on FF...

Its all about charge and exhaust face velocity. Which is why the GEs get screwed with the integrated exhaust manifold in the cylinder head. You would be able to tune runner/port length and diameter for a specific volume flow and speed to alter VE for whatever your goals/needs are.

In some cases you use this to draw intake air in with greater than 100% VE when you can also align the valve events to this effect.

Two strokes use this effect commonly to "supercharge" themselves

Which Gen Fit do you have Mark?

/I will clean this up when I get home, just a streaming conscious thought that came out like diarrhea when I stumbled on this thread again. Haven't posted tech info in a while

Last edited by wontfit; 06-12-2012 at 05:36 PM.

#30

Why not band saw the integrated exhaust manifold, port, and JB Weld it back in place??

I kid, partly. I can't see it being terribly hard to separate the manifold from the head, milling a flange, and tapping some studs for a nice 4-2-1 header. Granted, I have never seen the hot side of these engines nor the amount of space available between firewall and head. And yes, I do realize cost can be prohibitive, I'm just thinking out "loud."

I kid, partly. I can't see it being terribly hard to separate the manifold from the head, milling a flange, and tapping some studs for a nice 4-2-1 header. Granted, I have never seen the hot side of these engines nor the amount of space available between firewall and head. And yes, I do realize cost can be prohibitive, I'm just thinking out "loud."

#32

Why not band saw the integrated exhaust manifold, port, and JB Weld it back in place??

I kid, partly. I can't see it being terribly hard to separate the manifold from the head, milling a flange, and tapping some studs for a nice 4-2-1 header. Granted, I have never seen the hot side of these engines nor the amount of space available between firewall and head. And yes, I do realize cost can be prohibitive, I'm just thinking out "loud."

I kid, partly. I can't see it being terribly hard to separate the manifold from the head, milling a flange, and tapping some studs for a nice 4-2-1 header. Granted, I have never seen the hot side of these engines nor the amount of space available between firewall and head. And yes, I do realize cost can be prohibitive, I'm just thinking out "loud."

#33

Anyone get anywhere with cutting off the existing "headder"? Just curious to see what we have to work with. Or, if anyone has a cracked/bad head (didn't that loyd guy blow one up?) Or one from a crashed fit or something, I could take it to the shop at my school and hack it up on the bridgeports (well, not so much hack as cut off the headder then mill it flat and see what kind of material we have to work with).

I know next to nothing about tuning and such, but am studying mechanical engineering at school, so I would love to learn about it (and I can do simplish machining as well, since I do some for work).

I know next to nothing about tuning and such, but am studying mechanical engineering at school, so I would love to learn about it (and I can do simplish machining as well, since I do some for work).

Last edited by x_25; 04-04-2013 at 01:09 PM.

#35

Ahhhh, I see what you mean. There's not a whole lot of material there, is there? It looks like there might juuuust be space if it was cut as little as possible, just to where the ends of the "header" are. Though there wouldn't be a whole lot of room to drill and tap mounting holes.

Picture stolen from the TDR CR-Z build since I don't know where there are good pictures of the one from a fit. As far as I can gather though, the part I am interested in looking at is the same.

Picture stolen from the TDR CR-Z build since I don't know where there are good pictures of the one from a fit. As far as I can gather though, the part I am interested in looking at is the same.

#36

You'd have to cut deep enough in to have each cylinder separated, weld in material to machine flat, then machine a raised-boss mating surface for a gasket and still have enough room to tap for hardwire. All of this would still leave you trying to re-construct the galleys.

You'd be better off covering the R&D/Materials for a group like Bullet to make you a custom Billet head by the time you were done.

And.. its unnecessary. Just boost her.

You'd be better off covering the R&D/Materials for a group like Bullet to make you a custom Billet head by the time you were done.

And.. its unnecessary. Just boost her.

#37

You'd have to cut deep enough in to have each cylinder separated, weld in material to machine flat, then machine a raised-boss mating surface for a gasket and still have enough room to tap for hardwire. All of this would still leave you trying to re-construct the galleys.

You'd be better off covering the R&D/Materials for a group like Bullet to make you a custom Billet head by the time you were done.

And.. its unnecessary. Just boost her.

You'd be better off covering the R&D/Materials for a group like Bullet to make you a custom Billet head by the time you were done.

And.. its unnecessary. Just boost her.

I am one of those people that learn best by doing/taking things apart. I have had just about everything but the drivetrain appart on my fit so far (all two dozen or so parts that that is :P)

BTW, I enjoy reading your posts, I have learned a heck of a lot from them.

Last edited by x_25; 04-04-2013 at 02:35 PM.