Whiteline Rear Sway Bar

#1

Whiteline Rear Sway Bar

So i saw this the other day online.

Whiteline Adjustable Sway Bar 22mm Heavy Duty (3PT - Rear) for 2007-2008 Honda Fit - P/N: BHR86Z

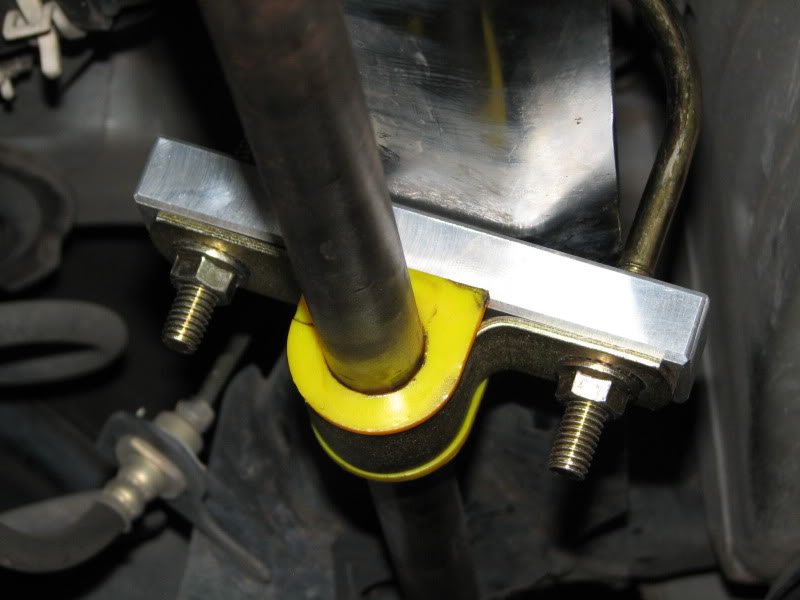

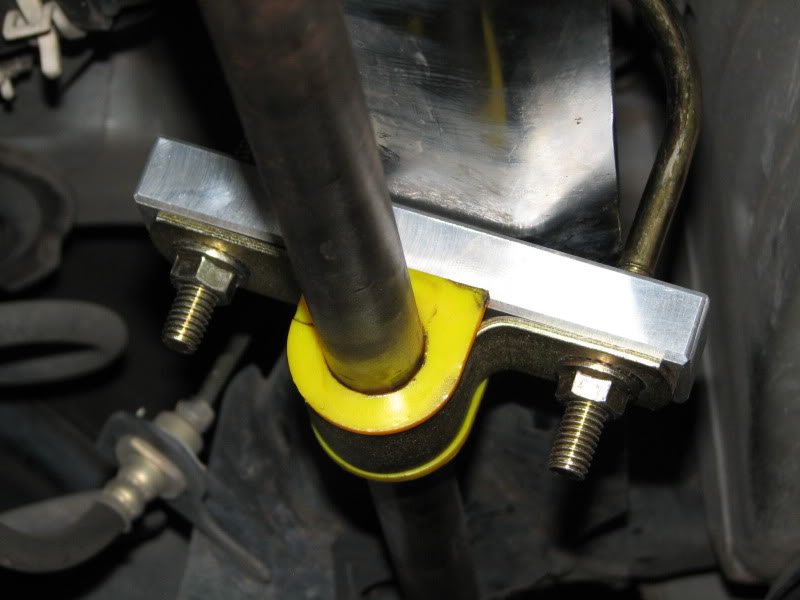

I emailed whiteline about how it mounts, and they sent me these pics.

I went ahead and ordered it to replace my progress bar. i'll give it a review when i get a chance to put it on.

It's pricer than the progress bar, but whiteline does make excellent products.

Whiteline Adjustable Sway Bar 22mm Heavy Duty (3PT - Rear) for 2007-2008 Honda Fit - P/N: BHR86Z

I emailed whiteline about how it mounts, and they sent me these pics.

I went ahead and ordered it to replace my progress bar. i'll give it a review when i get a chance to put it on.

It's pricer than the progress bar, but whiteline does make excellent products.

#2

Hmm, seems like an interesting way to mount the anti-sway bar (at least compared to Progress's method).

Can you post up a step by step D.I.Y. thread with your thoughts on the pros and cons between both bars once you get this one in?

Can you post up a step by step D.I.Y. thread with your thoughts on the pros and cons between both bars once you get this one in?

#4

im going to order this bar but i will make a few custom changes to it.

1. rear endlinks from power grid. (i have custom ones on my front)

2. Im going to skip the U clamps and just weld it to my torsion beam like a boss. wish me luck.

1. rear endlinks from power grid. (i have custom ones on my front)

2. Im going to skip the U clamps and just weld it to my torsion beam like a boss. wish me luck.

#5

#10

well, I had the ones included with the Skunk2 Pro C's. However, they leaked like a vaginal drip and yeah I could have fixed them and "resealed" them, but just the way they made them is CHEAP. Looks like less quality than the key ring that holds your keys together. almost like they took a paper clip, unwinded it, and used it like a garbage bag or bread loaf tie to seal their end links. I didn't want to keep having to band aid them. I also thought they were too long. Skunk2 didn't even include info on to how to PROPERLY adjust endlinks. I don't think they even know how, much less how to make a damn endlink.

PowerGrid really KNOWS their stuff. hands down, data tested, analyzed, and omg the customer support is superb.

skunk2 end link

now powergrid..

know how when some people get endlink noise they do the washer trick? with powergrid, you dont. shit is alll metal!!!!!!!!!!!!!

#16

after going back n forth with whiteline about different issues and getting different hardware to test...

it wont fit USDM.

There isnt enough space between the fuel line and the torsion beam. From their diagram, it looks like the fuel line goes over the torsion beam, whereas the USDM one goes under.

it wont fit USDM.

There isnt enough space between the fuel line and the torsion beam. From their diagram, it looks like the fuel line goes over the torsion beam, whereas the USDM one goes under.

#17

after going back n forth with whiteline about different issues and getting different hardware to test...

it wont fit USDM.

There isnt enough space between the fuel line and the torsion beam. From their diagram, it looks like the fuel line goes over the torsion beam, whereas the USDM one goes under.

it wont fit USDM.

There isnt enough space between the fuel line and the torsion beam. From their diagram, it looks like the fuel line goes over the torsion beam, whereas the USDM one goes under.

#18

Welding near the center of a torsion bar is a bad idea as it will change the crystalline structure (temper) of the metal and it will break. The way a torsion bar works is when one end moves up while the other moves down, the bar resists the movement keeping both wheels on the ground better. When both wheels move in the same direction, the bar does nothing because it has rotated with the wheels. The bar has to rotate, hence the bushings. If you weld it, no rotation past the weld, the twisting moment will be forever changed and the bar will not be the same.

#19

Welding near the center of a torsion bar is a bad idea as it will change the crystalline structure (temper) of the metal and it will break. The way a torsion bar works is when one end moves up while the other moves down, the bar resists the movement keeping both wheels on the ground better. When both wheels move in the same direction, the bar does nothing because it has rotated with the wheels. The bar has to rotate, hence the bushings. If you weld it, no rotation past the weld, the twisting moment will be forever changed and the bar will not be the same.

#20

after going back n forth with whiteline about different issues and getting different hardware to test...

it wont fit USDM.

There isnt enough space between the fuel line and the torsion beam. From their diagram, it looks like the fuel line goes over the torsion beam, whereas the USDM one goes under.

it wont fit USDM.

There isnt enough space between the fuel line and the torsion beam. From their diagram, it looks like the fuel line goes over the torsion beam, whereas the USDM one goes under.

so the Whiteline Sway Bar wont work on the usdm fit then or did you ever get it to work? is there away of moving the fuel line to go over the torsion beam? the reason why i ask is bc i want to get a rear sway bar for my fit and this is the only one that is a real sway bar. all the others that i have seen are just a glorified strut bar under the car.

if you didnt find away of using the whiteline sway bar what did you end up using for the rear sway bar?