Sprintex Supercharger Install

#125

tagging.... the GF's GE is not up to her old GTI's level of poke and she is begining to grumble about it...

DSM's info in here is GOLD FYI.

Hootie... you want a GD super charger setup? PM me im working on something...

DSM's info in here is GOLD FYI.

Hootie... you want a GD super charger setup? PM me im working on something...

#126

While on the topic of dyno. The information below was written by Evolve Automotive in the UK when asked about Dyno Testing – climate conditions, correction factors and repeatability. Evolve Automotive is a tuner specializes in performance upgrade for BMW and European cars. It is a general overview and not in anyway in-depth. This entire subject is vast and really requires more explanation. It is written in the hope that a maximum number of readers will understand it and that it will give a little more insight into the subject.

Abbreviations:

AT = Atmospheric Temperature

BP= Barometric Pressure

IT = Intake Temperature

RH = Relative Humidity

Generally speaking, the main factors which effect engine power output are as follows

- Atmospheric Air Temperature

- Barometric Pressure

- Relative Humidity (to a much lesser extent than the above two)

Let us look at Air temperature. It is common knowledge to most that as AT rises engine power drops off. As AT drops engine power increases. This many of you have experienced. On a hot summers day the engine will not feel as responsive nor will it accelerate the car as well. In comparison, on a cold morning the engine will feel electric giving far better throttle response and power. Why is this? Simple - the oxygen content of a lower air temperature is higher. Barometric pressure is also a very important factor. The higher the pressure the more dense the air (higher oxygen density) and the more power an engine will produce. As barometric pressure drops the oxygen density in the air is reduced and the engine will produce less power. As relative humidity rises, the water vapor in the air will displace the oxygen content and as a result reduces its density leading to lower engine power. This has a far lesser effect on engine power than the above two and is not taken into consideration by most standards. However the Dyno Dynamics machines do as the engineers want to achieve the most accurate power figures possible. So, as an example, if you took your car for a power test on a dyno on a hot day with a low BP and high AT the engine would make less power than on a day with a high BP and low AT.

Therefore the results would not be comparable. For this very reason the Society of Automotive Engineers (SAE) came up with a method of standardization such that the effects of air pressure, relative humidity and air temperature could be removed from the readings. This standardization gives us a value called the correction factor (CR) which is also known as atmospheric correction. With SAE we can then directly compare results from one day to another no matter what the atmospheric conditions were.

By using the dyno correction factor, power and torque readings can be compared for the same car on difference days with different barometric, air temperature and relative humidity.

Some of you may want to experiment with this, you'll need a scientific calculator. Modern computerized dyno's have the ability to have these variables inputted to generate the correction factor so we shouldn't have a problem. Simply take the readings from instruments reading the BP, RH and AT and input them into the software before carrying out the dyno session.

It is important to understand that BP, RH and AT vary dramatically from place to place, especially within buildings. BP is affected to a lesser degree than the other two. Dyno's are typically setup within workshops or purpose built dyno rooms. Therefore the BP, RH and AT sample must be taken from a suitable area and not just the nearest weather station which is an almost complete waste of time. If the weather station is say a few miles away it is very possible to have a situation where the area of the weather station has rainfall or overcast and where the dyno is located has clear skies and no rain.

These factors are very important as the atmospheric conditions will vary massively and therefore your correction factors are never consistent and therefore the results are nothing short of useless.

This is also further backed up by the fact that BP has an effect on RH. This is a separate subject altogether. Readers are asked to do their own research on this. RH and BP should be measured independently if possible due to the effect one has upon the other.

Therefore we can come to the very simple conclusion that BP, RH and AT must be measured within a very close radius to the dyno itself. This is very easy, there are weather stations available which measure all of these factors which can be placed in the dyno cell/room/area. But.....this is not enough and we can go one step further than this to have a more accurate correction factor and therefore standardization.

Dyno's such as the latest Dyno Dynamics machines have a built in weather station which constantly sample the BP, RH and AT. So our correction factors are changing on a live basis giving us corrected power and torque between even individual dyno runs. This might seem a little too much but take into consideration that even the best temperature controlled dyno cells are average at best at keeping things constant when you have a machine on a dyno under load dissipating huge amounts of gasses and heat constantly changing the conditions. On a dyno day for example with many cars coming on and off the dyno along with conditions naturally changing over the course of the day these variables can change dramatically. Therefore there is no better way than having a system where you have weather conditions being constantly monitored which in turn gives you the correct correction factor at all times (even from second to second). This also then means that even an average dyno cell will give excellent standardization and consistent results.

Does this all really work? I mean it's great in theory but does it work on the same cars all year round. Will the same car make the exact same power using the same fuel, dynoed in the same way in mid summer and mid winter? We are glad to report that over 2 years of testing the same cars all year round the system works within 2-3 bhp. This 2-3 bhp can be down to mechanical efficiency of the cars or a difference in tires. This actually comes as no surprise as many other dyno owners realize the same over a period of time. Certainly the dyno owners with integrated weather stations have far less work to do as far as standardization goes. Those that have to manually input atmospheric conditions still have issues. In the case of the Dyno Dynamics machines, the older machines came with a weather station which gave AT, BP and RH. However it was soon realized that these battery powered weather stations required their batteries to be changed very regularly otherwise the readings were incorrect. These atmospheric readings being incorrect lead to many dyno sessions being incorrect and as a result repeatability was compromised......heavily.

The power and graph shape is repeatable time and time again. The dyno software with it's built in weather station has what we believe to be the best standardizations in the market and it is this that makes the Dyno Dynamics so popular. How repeatable a dyno is defines its ultimate use.

If someone wants to know the difference between an upgrade and cannot fit his parts within a small space of time he can be assured that a properly standardized system will give him the actual difference in power output which resulted from his upgrades. Even if he comes back months later when the atmospheric conditions are completely different he'll know the actual difference all other factors remaining constant.

Conclusion:

Dyno output repeatability and consistency is everything and it is the atmospheric correction factors which allow a dyno to be one of the most important and powerful tools for any serious tuner.

Abbreviations:

AT = Atmospheric Temperature

BP= Barometric Pressure

IT = Intake Temperature

RH = Relative Humidity

Generally speaking, the main factors which effect engine power output are as follows

- Atmospheric Air Temperature

- Barometric Pressure

- Relative Humidity (to a much lesser extent than the above two)

Let us look at Air temperature. It is common knowledge to most that as AT rises engine power drops off. As AT drops engine power increases. This many of you have experienced. On a hot summers day the engine will not feel as responsive nor will it accelerate the car as well. In comparison, on a cold morning the engine will feel electric giving far better throttle response and power. Why is this? Simple - the oxygen content of a lower air temperature is higher. Barometric pressure is also a very important factor. The higher the pressure the more dense the air (higher oxygen density) and the more power an engine will produce. As barometric pressure drops the oxygen density in the air is reduced and the engine will produce less power. As relative humidity rises, the water vapor in the air will displace the oxygen content and as a result reduces its density leading to lower engine power. This has a far lesser effect on engine power than the above two and is not taken into consideration by most standards. However the Dyno Dynamics machines do as the engineers want to achieve the most accurate power figures possible. So, as an example, if you took your car for a power test on a dyno on a hot day with a low BP and high AT the engine would make less power than on a day with a high BP and low AT.

Therefore the results would not be comparable. For this very reason the Society of Automotive Engineers (SAE) came up with a method of standardization such that the effects of air pressure, relative humidity and air temperature could be removed from the readings. This standardization gives us a value called the correction factor (CR) which is also known as atmospheric correction. With SAE we can then directly compare results from one day to another no matter what the atmospheric conditions were.

By using the dyno correction factor, power and torque readings can be compared for the same car on difference days with different barometric, air temperature and relative humidity.

Some of you may want to experiment with this, you'll need a scientific calculator. Modern computerized dyno's have the ability to have these variables inputted to generate the correction factor so we shouldn't have a problem. Simply take the readings from instruments reading the BP, RH and AT and input them into the software before carrying out the dyno session.

It is important to understand that BP, RH and AT vary dramatically from place to place, especially within buildings. BP is affected to a lesser degree than the other two. Dyno's are typically setup within workshops or purpose built dyno rooms. Therefore the BP, RH and AT sample must be taken from a suitable area and not just the nearest weather station which is an almost complete waste of time. If the weather station is say a few miles away it is very possible to have a situation where the area of the weather station has rainfall or overcast and where the dyno is located has clear skies and no rain.

These factors are very important as the atmospheric conditions will vary massively and therefore your correction factors are never consistent and therefore the results are nothing short of useless.

This is also further backed up by the fact that BP has an effect on RH. This is a separate subject altogether. Readers are asked to do their own research on this. RH and BP should be measured independently if possible due to the effect one has upon the other.

Therefore we can come to the very simple conclusion that BP, RH and AT must be measured within a very close radius to the dyno itself. This is very easy, there are weather stations available which measure all of these factors which can be placed in the dyno cell/room/area. But.....this is not enough and we can go one step further than this to have a more accurate correction factor and therefore standardization.

Dyno's such as the latest Dyno Dynamics machines have a built in weather station which constantly sample the BP, RH and AT. So our correction factors are changing on a live basis giving us corrected power and torque between even individual dyno runs. This might seem a little too much but take into consideration that even the best temperature controlled dyno cells are average at best at keeping things constant when you have a machine on a dyno under load dissipating huge amounts of gasses and heat constantly changing the conditions. On a dyno day for example with many cars coming on and off the dyno along with conditions naturally changing over the course of the day these variables can change dramatically. Therefore there is no better way than having a system where you have weather conditions being constantly monitored which in turn gives you the correct correction factor at all times (even from second to second). This also then means that even an average dyno cell will give excellent standardization and consistent results.

Does this all really work? I mean it's great in theory but does it work on the same cars all year round. Will the same car make the exact same power using the same fuel, dynoed in the same way in mid summer and mid winter? We are glad to report that over 2 years of testing the same cars all year round the system works within 2-3 bhp. This 2-3 bhp can be down to mechanical efficiency of the cars or a difference in tires. This actually comes as no surprise as many other dyno owners realize the same over a period of time. Certainly the dyno owners with integrated weather stations have far less work to do as far as standardization goes. Those that have to manually input atmospheric conditions still have issues. In the case of the Dyno Dynamics machines, the older machines came with a weather station which gave AT, BP and RH. However it was soon realized that these battery powered weather stations required their batteries to be changed very regularly otherwise the readings were incorrect. These atmospheric readings being incorrect lead to many dyno sessions being incorrect and as a result repeatability was compromised......heavily.

The power and graph shape is repeatable time and time again. The dyno software with it's built in weather station has what we believe to be the best standardizations in the market and it is this that makes the Dyno Dynamics so popular. How repeatable a dyno is defines its ultimate use.

If someone wants to know the difference between an upgrade and cannot fit his parts within a small space of time he can be assured that a properly standardized system will give him the actual difference in power output which resulted from his upgrades. Even if he comes back months later when the atmospheric conditions are completely different he'll know the actual difference all other factors remaining constant.

Conclusion:

Dyno output repeatability and consistency is everything and it is the atmospheric correction factors which allow a dyno to be one of the most important and powerful tools for any serious tuner.

#128

Just got my car back. My tuner double checked everything and was about to open the blower to check if there was a leak somewhere but as he was test driving it he noticed a sound that gave him a clue. It was the fuel. I had been using 87 gas until recently when I turned in the sc to him and changed to 91. I only filled it with 4 gallons though. He completely emptied the car and filly filled the tank to 91. That solved the issue apparently. No more issues at 3k rpms!! His buddy checked the wiring diagram three times and said everything was correct before they found out it was the fuel. My tuner was about to ask Gary again for another one but Gary said there is none left and everything should be correct with the one he sent him. Who would think that such a simple issue was overlooked.

I did however get a check engine light after i drove it back to my apt, turned it off, and then had to leave again. I also noticed a rattling/spatting sound every time I pushed on the gas pedal hard. I called my tuner back right away and notified him. The rattling sound he said could be due to the fuel? Or was it the fuel injector? I forget but I'll be bringing it back to him tomorrow afternoon to check on it. The car runs fine and seems to be boosting appropriately. I'm able to pass 3k rpm no problem.

I did however get a check engine light after i drove it back to my apt, turned it off, and then had to leave again. I also noticed a rattling/spatting sound every time I pushed on the gas pedal hard. I called my tuner back right away and notified him. The rattling sound he said could be due to the fuel? Or was it the fuel injector? I forget but I'll be bringing it back to him tomorrow afternoon to check on it. The car runs fine and seems to be boosting appropriately. I'm able to pass 3k rpm no problem.

#129

My injen cai was reinstalled and he tuned it to both the injen and to the airbox along with my mugen exhaust. The car sounds pretty much stock like Steven mentioned and only here the sc when you punch it. Noob question but you think an oil cooler will be helpful or recommended? I was thinking of getting the cusco universal oil cooler kit. Kinda pricey though. Any other universal oil cooler kits out there?

Last edited by Fuzzyfunk; 12-26-2013 at 11:12 PM.

#130

Gary, what is the flow rate of the Bosch 028-158-193 supplementary injector? The only unofficial information that I can dig out is 550 cc/min at 43.5 psi. I am trying to determine the maximum potential of the fuel system.

#131

That's what SAE J1349 is for. Basically, just use a dyno for quantifying/qualifying changes made.

Like anything else, a singular data point is near meaningless.

To add to that bit Steven posted, I know of at least one dyno local to me that has the weather pack mounted in a spot (intentionally or not) that will skew the results.

Last edited by DiamondStarMonsters; 12-27-2013 at 07:04 AM.

#132

Edit: I should mention I'm thoroughly enjoying this thread, as it lets my Fit live vicariously through yours since it's performance plans were sacrificed for the race car.

Last edited by DiamondStarMonsters; 12-27-2013 at 07:16 AM.

#133

Been reading this thread with interest cannot really add any technical information but I am glad to see people venturing forward with this to keep the product available.

I am interest in the future looking forward to some real world numbers like hp, mpg, and any other performance increase. Keep up the good work.

I am interest in the future looking forward to some real world numbers like hp, mpg, and any other performance increase. Keep up the good work.

#134

So I've gotten a few more miles on the car and I can say it is a dramatic power increase. I have not noticed any drivability issues. I don't plan on dynoing it but I will use the Android Torque app to display calculated hp. The best I could hit before the SC was 98hp. So when I get some dry pavement I'll try it with the SC. I'm not sure how the car calculates MPG? The indicator is about the same before the SC. So if the car calculates this with injector data this will probably be off.

#135

It's about 370cc on your static FP rating. Jeeps run similar fuel pressures, but still vary +/- 5psi year-to-year. I have no idea why the actual flow information on them is so hard to find for us normal folk.

#137

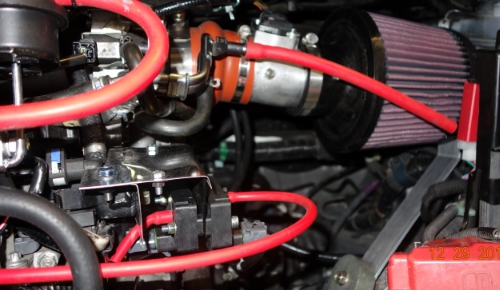

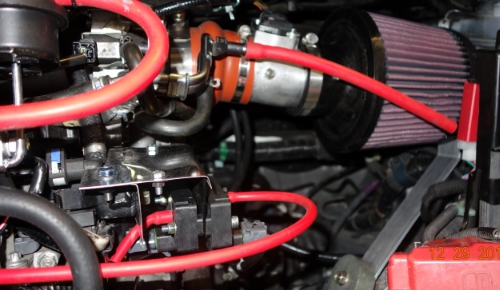

Here is my DIY short ram intake made with a 4” long 2 ˝” diameter aluminum pipe, Hitachi MAP flange for a LS3/LS7 Corvette and a K&N RX 4950 filter. An air filter brace need to be made so it doesn’t rub against the SMT8L and the brake reservoir. The filter top of the K&N has provision for a nut and a bolt for optional bracing that made thing easy. A heat shield needs to be added. PCV is venting to atmosphere now but will be connect to the intake. The SRI gives the car a different character. Upon stepping on the gas there is a very audible wheeze. Wheeze I am the GEICO pig driving a supercharged Honda Fit and off I go. After the wheeze comes the supercharger whine. Definitely not expect from the SRI. The car seems more responsive from the initial drive around the neighborhood.

#138

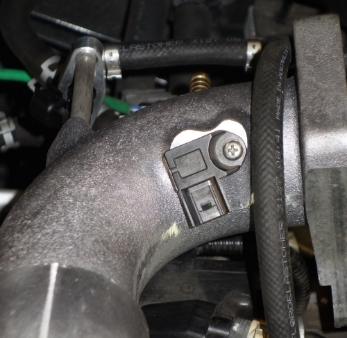

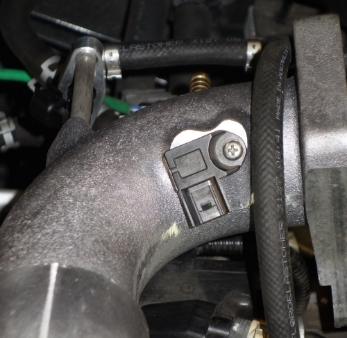

The supplementary injector is mounted in the inlet pipe. You can see the injector underneath the green wire. The throttle body is mounted to the right. How do you calculate the maximum theoretical horse power from this fueling configuration with the stock and supplementary injectors.

Is there another mathematical formula that is more applicable?

Is there another mathematical formula that is more applicable?

#139

Here is my DIY short ram intake made with a 4” long 2 ˝” diameter aluminum pipe, Hitachi MAP flange for a LS3/LS7 Corvette and a K&N RX 4950 filter. An air filter brace need to be made so it doesn’t rub against the SMT8L and the brake reservoir. The filter top of the K&N has provision for a nut and a bolt for optional bracing that made thing easy. A heat shield needs to be added. PCV is venting to atmosphere now but will be connect to the intake. The SRI gives the car a different character. Upon stepping on the gas there is a very audible wheeze. Wheeze I am the GEICO pig driving a supercharged Honda Fit and off I go. After the wheeze comes the supercharger whine. Definitely not expect from the SRI. The car seems more responsive from the initial drive around the neighborhood.

Quick question,

is it still possible to use the K&N Kit (the one that is made for standard Honda Fit GE) with Sprintex Supercharger ?

#140

It should work fine. I had the stock air box before I decided to install my DIY short ram intake. Here are two more pictures.

The brackets for the map sensors, for the K&N RX4950 and the heat shield was a pain to make.

The engine bay look so empty without the air box.

The brackets for the map sensors, for the K&N RX4950 and the heat shield was a pain to make.

The engine bay look so empty without the air box.

Last edited by Steven Hung; 12-29-2013 at 08:55 AM.